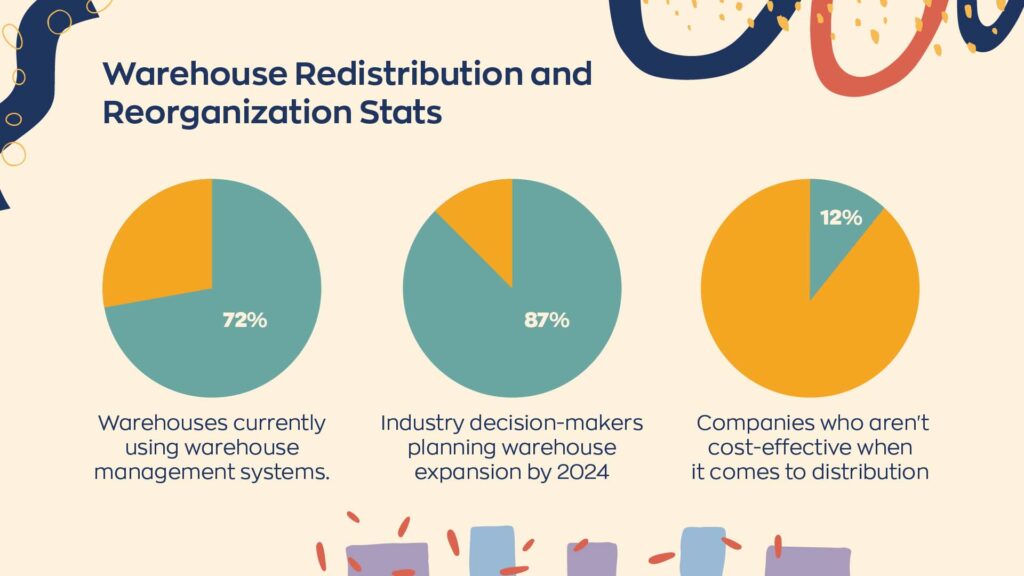

Optimized inventory management is the key to maintaining adequate stock levels and keeping everything organized and running smoothly. However, even with the best warehouse management software, you may find that your current facility is holding you back and is no longer serving all of your business’s needs. Whether this is due to growth, overstock, or even productivity gaps, it may be time to expand and redistribute your inventory to another warehouse.

Moving to a new warehouse or relocating to another with a better lease and location is an opportunity to better optimize your inventory and ensure your current or additional spaces are running as efficiently as possible. However, when you’re initially redistributing inventory, things can quickly become disorganized, and you could potentially lose track of stock if you aren’t careful.

This article will cover the process of redistributing inventory. Keeping everything organized along the way is key to ensuring a smooth transition. These tips could be useful for anyone working in warehouse management. Whether you’re a new warehouse owner or a seasoned expert relocating, expanding, redistributing, or even acquiring consigned items.

Assess space efficiency

To ensure your business is running as optimally as possible, your warehouse space needs to be efficient. This means you need to

- Have a smart layout to maximize your space;

- Properly organize and label everything;

- Establish and adhere to safety standards and protocols;

- Adequately train staff;

- Utilize quality inventory and warehouse management systems.

Space inefficiency could end up costing you money. This could be through delays, inaccurate stock and inventory records, deadstock, and other issues.

Determine the need for redistribution

After assessing efficiency, this will naturally lead you to why there is a need for redistribution. Even if you are simply expanding because your business is growing and you have run out of space. Evaluating the situation is important in order to be sure you’re not carrying over any inefficiencies to your new warehouse.

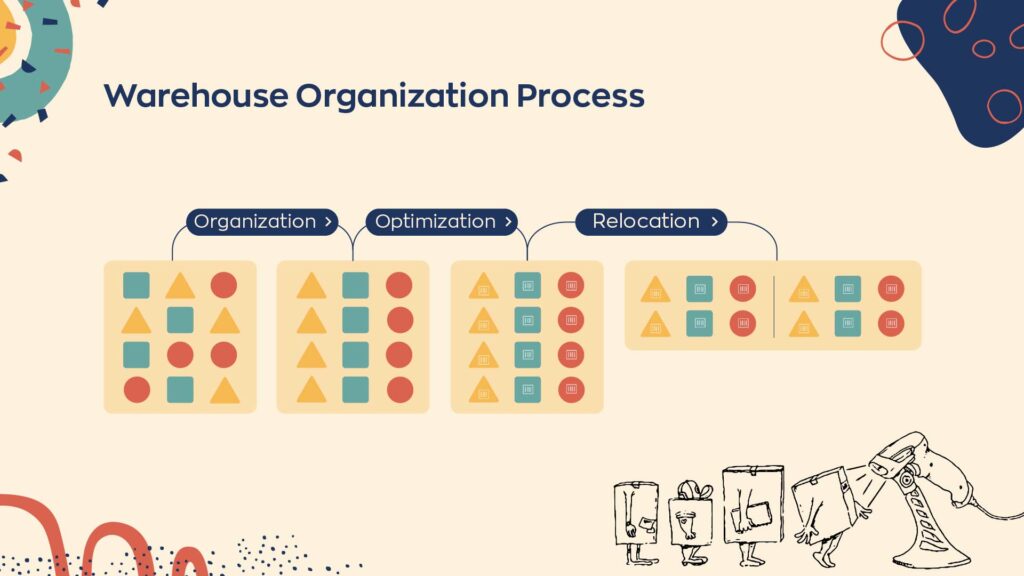

Reorganization

In many cases, you need to redistribute for better organization of your overall inventory and stock. If your current space is too small, for example, or simply doesn’t suit your business’s specific needs and demands, then you may find everything is a challenge to keep organized. In this situation expanding to a new facility can help you better manage your inventory. A new space will ensure there is enough space to keep your inventory properly stored, labeled, and easily accessed.

Optimization

An optimized warehouse is not only one that has a well-organized inventory but one that also uses automation to improve the overall supply chain process. This ensures there are no issues with safety stock or out-of-stock situations. It’s also essential to have a space conducive to a healthy, safe, and productive work environment for staff. If your current space does not allow you to properly implement the needed tools and systems or if it’s keeping your staff from getting their job done, then it is likely time to redistribute to a new space.

Relocation

Sometimes the need for redistribution is simply because your current warehouse no longer meets your businesses needs. Lots of companies relocate for many reasons. For example, if your warehouse is too far away and you’re paying higher transportation costs, or it’s taking too long for items to get where they need to be, redistributing to a more ideal location might be a wise choice. No matter where you relocate to, using the proper tools and software, like warehouse management software, ensures all of your inventory and stock are transferred without a hitch.

Use organization tools

A well-organized warehouse allows your employees to easily move about the space, better find and access what they need, and overall have more productive shifts. An unorganized warehouse will negatively impact the supply chain process and can create an unhealthy and unsafe work environment for staff. So it’s essential to ensure you are using the right tools and systems to keep things organized during and after the redistribution process.

Labels

Labeling tools are a must for any warehouse. It’s crucial to clearly label individual items as well as the bins you store them in. This will make it easier for employees to navigate the warehouse and find what they’re looking for.

This might seem like such a simple thing, but glossing over this step and neglecting to properly label each item during and after redistribution is sure to cause issues in the future for your business. It’s also a good idea to include proper signage and imagery around the warehouse when labeling. Doing so can help employees locate areas easier and keep themselves safe.

When designing your labels, you’ll likely want to take advantage of barcodes. Creating your own barcodes is an excellent method of managing inventory. Barcodes are inexpensive to implement in your inventory organization. They can reduce human error, and are more efficient than manual data entry.

Software

All-in-one, comprehensive inventory management software is essential when you’re redistributing inventory and moving to a new location. If your company is not already using quality warehouse management software, it would be wise to do so during redistribution and going forward.

These days, a simple Excel spreadsheet will not cut it. The right software can help you keep track of stock and incoming orders, fulfill orders, set reorder points, generate barcodes, as well as track manufacturing and component costs.

Smart storage

Not all warehouses are the same, nor are the individual storage needs for each business and its specific inventory and stock. So there is no one right way to organize a warehouse and store items. You will need to thoroughly evaluate your inventory and stock to determine which storage solutions are right for you. This can include keeping best-selling stock towards the front, keeping aisles open for traffic, and stacking bins.

Some popular warehouse storage methods and solutions include:

- Double-depth racks;

- Floor/block stacking;

- Pallet-flow racking;

- Static shelving;

- Mobile shelving;

- Mezzanine flooring.

Get employees on board

Another key element when redistributing inventory is to make sure everyone is on board. If you leave employees in the dark it can slow down the process and result in a lack of productivity. Good communication and employee satisfaction are essential.

Improve communication

A warehouse is a large space, so it’s essential to have good communication between employees and management to ensure everything is running properly. This can get even more complicated if you are having to communicate between more than one warehouse. So it’s essential to not only have good verbal face-to-face communication but also to use quality communication tools and systems to make it easier to communicate across distances. These can include digitally connected wearables, radios, phone systems, and tablet devices.

Survey satisfaction

Without your employees, you wouldn’t have a business. This is why it’s essential to not only ensure your inventory is organized but that your employees are satisfied. Happy employees are known to be more productive. One way to stay on top of employee satisfaction and ensure their needs are being met is to conduct surveys.

Your employees are the ones who are deeply involved with the warehouse operations. So a survey can help you identify pain points with your processes. You could use this data to provide an overall better system and working environment moving forward.

Provide incentives

If you want your warehouse to run efficiently, it’s important to provide incentives to show your employees that you appreciate them and care about their wellbeing.

From the initial onboarding process to employee training, provide a quality work environment that shows your employees you have their health, safety, and wellbeing in mind. This is yet another area that can be improved with the right warehouse management software. When your warehouse is optimized and organized, you are more capable of ensuring your employees are well taken care of.

Furthermore, fully comprehensive software can also improve the customer onboarding process, and customer satisfaction and employee satisfaction are often closely linked. Overall, the right tools and systems can improve the redistribution process. This will help you focus on your company’s needs to ensure a smooth process now and in the future.

0 Comments