Key takeaways

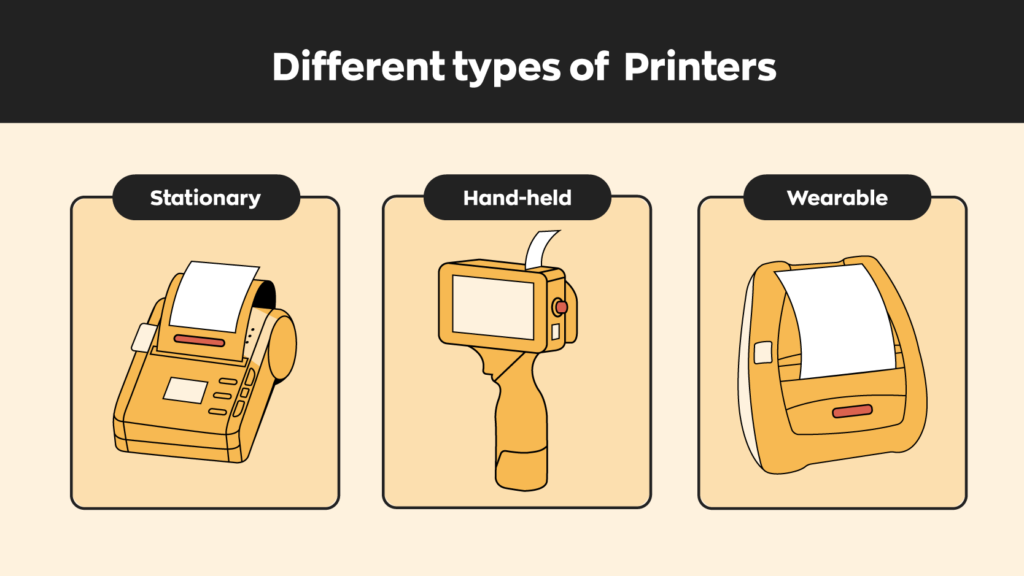

- Barcode label printers can be separated into two main categories: stationary and portable. Stationary printers remain in a fixed location and require a power source, and portable printers are handheld or wearable and are suitable for mobile tasks.

- Established brands like Dymo, Brother, and Zebra are known for reliability and performance, though they may come at a higher cost compared to newer, less-proven brands.

- When you choose a barcode label printer, you should assess the environment in which it will be used; for instance, warehouse staff may benefit more from portable devices, while office settings might favor stationary printers.

- In demanding environments, investing in industrial-grade printers that are resistant to drops, heat, and water can be cost-effective over time despite their higher initial price.

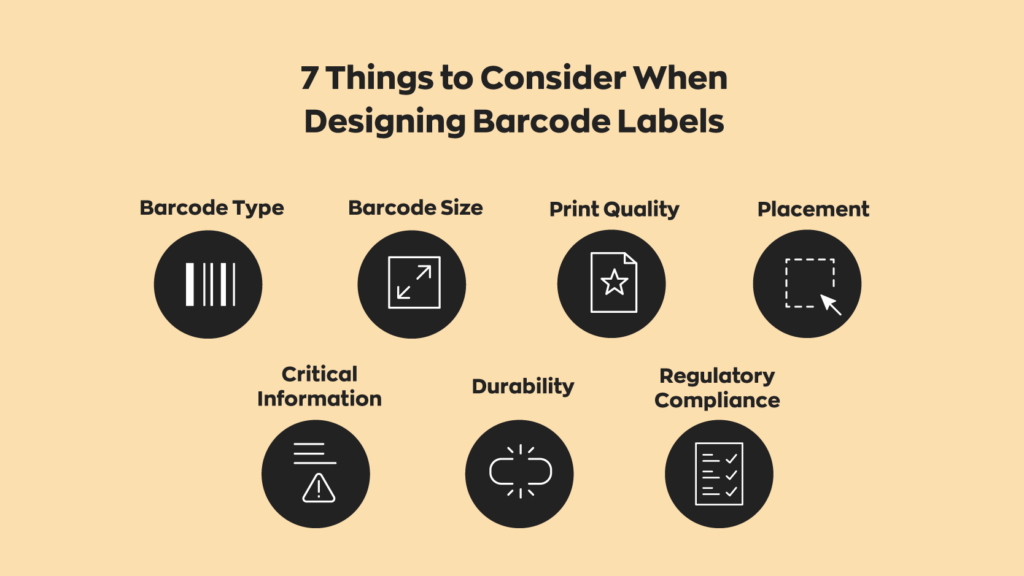

- You should consider size, placement, and color when designing your barcode labels.

- You can create barcodes for your barcode labels by using a font, an online barcode generator, or barcoding software. Those who require registered barcodes for retail environments can purchase barcodes from GS1.

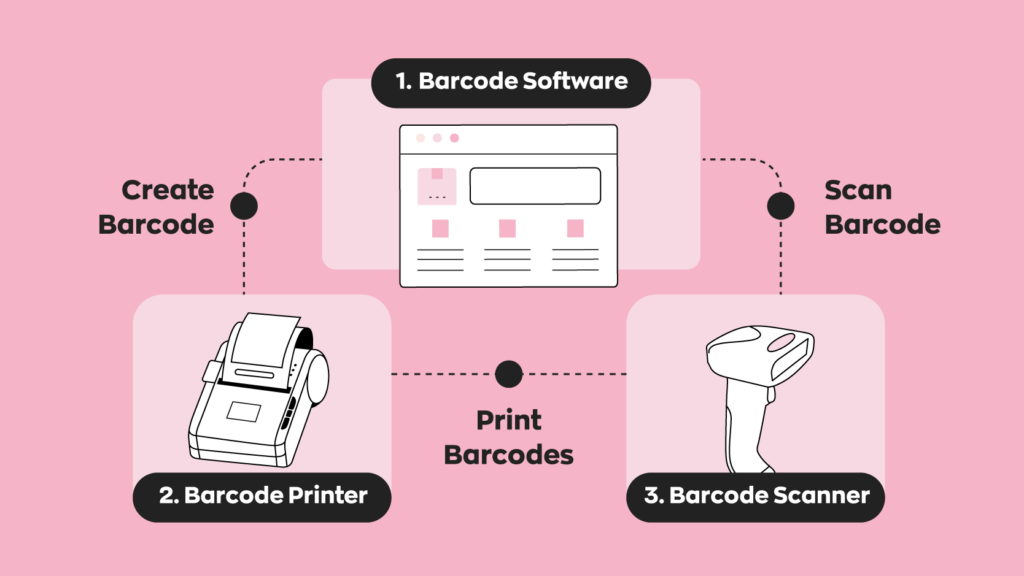

- A barcode label printer is just one piece of the puzzle when it comes to a complete barcoding system. You’ll also need barcode scanners, barcode software, and, of course, the barcodes themselves.

Barcodes are important. That’s no secret. Even in 2025, with seemingly everything moving towards a digital format, barcodes continue to stand the test of time. Even more “advanced” devices like RFID tags have failed to replace barcodes entirely. But the barcodes themselves are just one part of a complete system. You’ll need a few things to start, and one major component is a barcode label printer.

On top of there being different types of barcodes, there’s also different types of barcode label printers. So, which barcode label printer is best for you? What factors should you consider when selecting a barcode label printer? Moreover, what should you keep in mind when barcode printing?

With those questions in mind, let’s get into it!

[If you want to learn everything there is to know about barcodes, check out our Ultimate Barcoding Guide.]

Types of barcode label printers

Broadly speaking, there are two types of barcode printers: stationary and handheld. As their vocabulary suggests, a stationary barcode label printer needs to stay in one place and requires its own power source. Handheld barcode printers, on the other hand, are smaller devices meant to be hand-operated. Within these two groupings, however, there are differences to consider; more on that in a moment.

As for brands, Dymo, Brother, and Zebra are well-renowned for their operational capabilities and overall reliability. New brands and manufacturers continue to enter the market, but none have the prestige of the three aforementioned brands. It’s possible to save in the short term by selecting a more affordable brand, but this could cost more than it saves in the long run.

Factors to consider when choosing a barcode label printer

The most important thing to consider when settling for a barcode label printer is the environment in which you will use it. For example, a warehouse picker would appreciate a handheld device instead of being forced to walk back and forth at a moment’s notice. On the other hand, a desk worker is relatively stationary and will be within arms’ reach of a stationary printer more often than not.

As we mentioned above, though, there are more factors to consider than just stationary vs. handheld. Industrial-grade scanners, for example, are built to be drop-proof, heatproof, waterproof, and so on. A more durable barcode printer will undoubtedly have a higher price tag. But if you find yourself replacing printers every week, the more durable options will pay for themselves over time.

Some industries also have specialized designs. While not as standard as stationary and handheld printers, wearable barcode printers are crucial in some fields. There’s one major downside to handheld printers. By definition, they require at least one hand to operate. That doesn’t sound like a big deal, right? But there are industries where the need for both hands can arise at a moment’s notice. It’s a grim consideration, but freeing up one hand can sometimes be the difference between safety and injury.

What else will you need other than a barcode printer?

As valuable as barcodes (and their printers) are, they’re just one piece of the puzzle. You’ll still need two other components to build a complete barcode system.

Barcode scanners

Having barcode labels won’t do you much good if you don’t have a way of reading them. For this, you’ll need a barcode scanner. These come in many shapes and sizes, and much like barcode printers, deciding on a barcode scanner will depend on your needs.

For example, a wired barcode scanner would work fine if you’re scanning at one designated location. But you should probably consider a wireless smart scanner if you need mobility, like for warehouse picking.

Barcoding software

Barcodes are machine-readable data. The computer will interpret the lines and spaces in a barcode and translate them into an alphanumeric code. The computer would then locate the information connected to that code stored inside a software system. If there’s nothing to match it to, the data itself is meaningless.

It’s an oversimplification, but you can consider a barcode system as a data bank. The barcodes represent information stored inside that data bank, and barcode scanners match the product in question to that information.

Today, inventory management software like inFlow has a built-in barcode system. Of course, inventory management software isn’t a strict requirement. But if you want to get the most out of your barcodes, it doesn’t make sense not to have one.

How do I create barcodes?

There’s two available avenues here. First, you can purchase barcodes from GS1, the global distributor. Each of these barcodes is unique to a product and is globally recognized. While versatile, these barcodes can also be expensive, as they cost an annual fee to maintain. The more barcodes, the more you pay annually.

However, they have an option of buying single GTINs for $30 with no renewal fee. If you need less than ten barcodes, we recommend this option. In fact, we’ve even recently partnered with GS1 to sell their official barcodes through our inFlow GTIN Barcode Shop.

Alternatively, you can create your own barcode ecosystem with barcode generators. inFlow, for example, can create unique barcodes for every product your business offers. And unlike GS1, there are no fees. Remember, though, that this is an ecosystem exclusive to you. The barcodes will only be recognized in your system. Outside businesses and retailers won’t be able to read them.

Barcode label printing best practices

Here are some things to remember when designing, printing, and applying your barcode labels.

- Size and placement: The bigger, the better, but bigger means you’ll run through paper faster. Try to find a balance between size and readability. In that same vein, it’s also important to figure out a suitable placement and then standardize that placement. If barcodes end up in different places on the same product, your workers will end up wasting time looking for labels. It’s best to place barcodes somewhere easy to find but where they won’t be easily destroyed or disfigured.

- Color: While it might be tempting to create visually appealing barcodes, there’s a reason that most places stick with black-and-white: contrast. If there’s not enough contrast between the two colors, the machines might be unable to read the barcodes. For this reason, it’s best to stick with black-and-white barcodes and use colors elsewhere on your labels.

- Human readable vs. machine-readable only: this one is more complex. If you walk into any major retailer and look at a random barcode, you’ll probably see numbers and letters under the stripes. That’s the human-readable portion of the barcode. Because we humans can’t read barcodes (at least, not yet), human-readable text is placed at the bottom in case something goes wrong. You can go without it, but it’s best to have it as a contingency.

How can inFlow help?

Barcodes are a crucial part of any business that handles inventory. That hasn’t changed since their introduction and likely won’t change for years to come. And while they haven’t changed much over time, the software surrounding them has seen many improvements. inFlow, for example, serves as an all-in-one platform for your barcoding needs. Along with built-in barcode generation, inFlow’s mobile app turns any mobile phone into a scanner, enabling work on the go.

0 Comments