No matter where you live, you almost certainly see barcode labels on a regular basis. Businesses slap them on just about everything– everyday products, food products– they’re even barcoding shelves! There’s a good reason for this. Barcodes are some of the most powerful tools that businesses use. For anyone starting out, though, figuring out how to use them can be a bit tricky. So: how do you make use of barcode labels? And how do you even get your hands on them in the first place?

What is a barcode label?

Before answering what a barcode label is, let’s quickly go over what a barcode is. We’ve already created an in-depth guide about barcodes, so we won’t spend much time talking about it here.

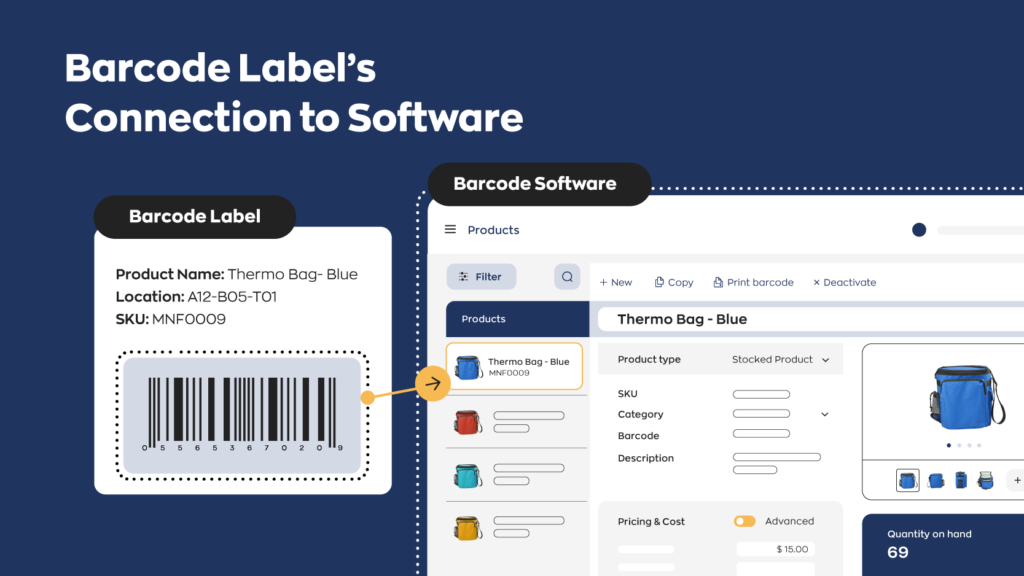

In simple terms, a barcode is an image that contains information about a specific product. The information is translated into black-and-white stripes that are impossible for humans to read. Computers, on the other hand, can read these symbols instantly with the use of a scanner. Barcodes can contain a variety of information: SKU, weight, shape, size, and so on.

Keep in mind that this is an extremely simplified explanation: there’s a lot that goes into barcodes. Barcode labels, much like barcodes themselves, include different information depending on their use. For example, you might decide to keep your barcode label simple and include a barcode and nothing else. Or you might opt for a more human-friendly barcode label and include information such as product name, variant type, SKU, location, and so on. Having additional information like this on your barcode labels is useful for employees to verify inventory at a glance.

Why do businesses use barcode labels?

To a business, time and money are the same thing. For the most part, employees complete the day, and businesses compensate these employees for their time with money. Simple, right? This means that time-saving measures are typically cost-saving measures as well.

For example, think of the last time you went to a grocery store. How many products did you buy? Ten? Fifteen? Whatever the number, the cashier probably scanned the barcode labels to check you out. Now imagine if that cashier had to look up every item individually. It’d take a lot longer, which means a decrease in sales. Multiply that loss by however many cashier lanes there are, and you start to see the importance of time.

The benefits of a barcode system aren’t limited to sales, either. Barcode labeling allows employees to look up product information with a single scan and keeps your records more accurate. This saves time and money, freeing up resources that can then be used elsewhere.

Retail stores are the most obvious example because everyone experiences them, but all sorts of businesses use barcode labels.

Manufacturers, especially, can benefit from implementing barcode labels into their workflow. Barcoding shelves, components, work-in-progress inventory, and finished products mean you can easily track all of your inputs and outputs without having to worry about tons of manual data entry.

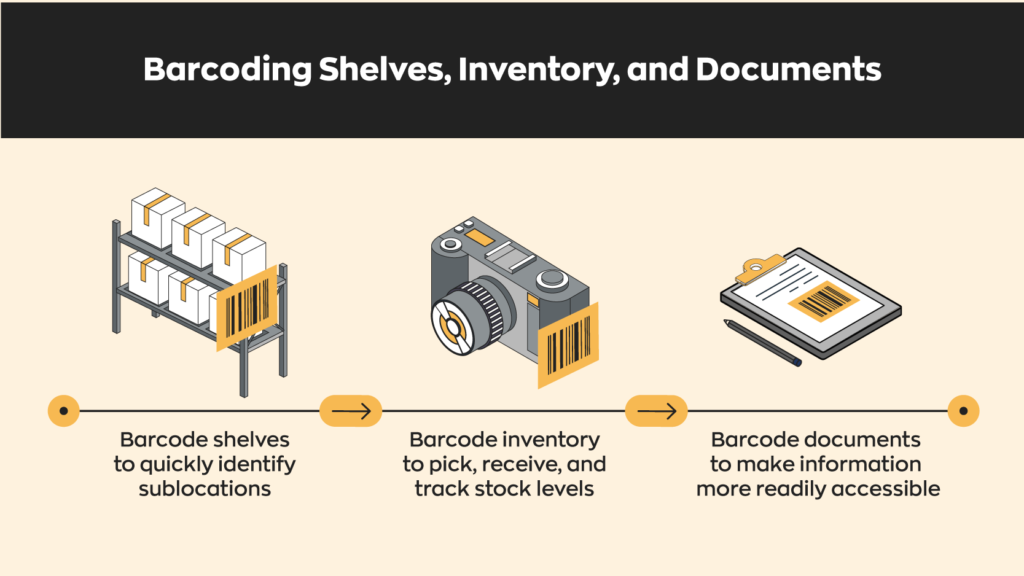

What should you put barcode labels on?

The short answer: everything! You can put them on all different types of inventory, assets, and documents. You could even be barcoding shelves, racks, and bins. Remember, though– put the barcode labels somewhere they’re easy to see and scan! You don’t want to waste your valuable time looking for a tiny sticker on a huge product. Not to mention many barcode scanners have a hard time reading super small barcode labels.

When properly set up and managed, the more barcode labels you have, the more effective your system will be. Barcode labels on your inventory will make your picking and packing a breeze. Barcoding shelves would allow workers to check what products are in a sublocation with just a single scan. This saves time and, in the long run, money.

What do you need to start barcoding shelves and inventory?

Bottom line up front: while it’s still possible to use old-school methods like spreadsheets or word documents with barcodes, they’re incredibly impractical. If you’re going through the effort of implementing barcode labels, you’re going to want to unlock their full potential. To do that, you’ll need barcoding software. As your product lineup grows, manually managing a system can become overwhelming– if not impossible. Remember: time is money. The amount of time barcoding software will save you make it well worth the price.

The hardware side of things is a bit simpler. Here’s what you’ll need:

- Printer: while you could get by using a standard office printer, we recommend investing in something made for label printing. Often these printers will come with software that will help you design and create your barcode labels. In our experience, the software can be hit or miss, which is why we designed our own label designer (more on that later).

- Barcode scanner: you could pick up a new scanner, or you could turn your phone into one with just a few taps. inFlow’s mobile app turns your mobile phone into a handheld scanner, letting anyone scan anything right from the shelf. Keep in mind, though, that there are times when a smartphone camera just won’t cut it.

Where do you get barcodes?

If you’re just starting out, there’s an important question: where do you get barcodes? The most cost-effective option would be to create your own barcodes with either a barcode generator or a barcode font. However, this is really only an option if you’re using barcodes for internal inventory management. If you’re using barcodes on products that are intended to be used externally, for example, if you’re selling products through Amazon, you’ll need officially registered barcodes. These barcodes all come from the same place, GS1.

Barcodes registered through GS1 have their own unique global trade item number (GTIN). These numbers are recognized globally and verify the product’s authenticity. The good news is buying official GS1 barcodes has never been easier. We’ve partnered up with GS1 US to make buying barcodes as easy as possible with our inFlow GTIN Barcode Shop.

How does inFlow fit in?

Barcodes are as powerful as they are versatile. They can optimize your workflow, increase overall productivity, and save thousands in the long run. At the same time, if you use it just for sales, you’re wasting its potential. The more deeply you integrate your barcoding system, the more you’ll get out of it. inFlow is an all-in-one barcoding system for anyone looking to introduce barcodes into their inventory management. We know how important barcode labeling is to our customers, which is why we’ve developed our very own label designer tool. Now you can easily design, create, and print your own custom barcode labels right inside of inFlow!

0 Comments