The logistics world has seen many innovations over the years, from barcodes to RFIDs and beyond. And now, in the modern world of AI, we’re seeing something new emerge: computer vision for inventory monitoring. Computer vision relies on cameras and image recognition software to track product movement through warehouses and distribution centers. These AI systems can identify products, read labels, and get a real-time inventory count.

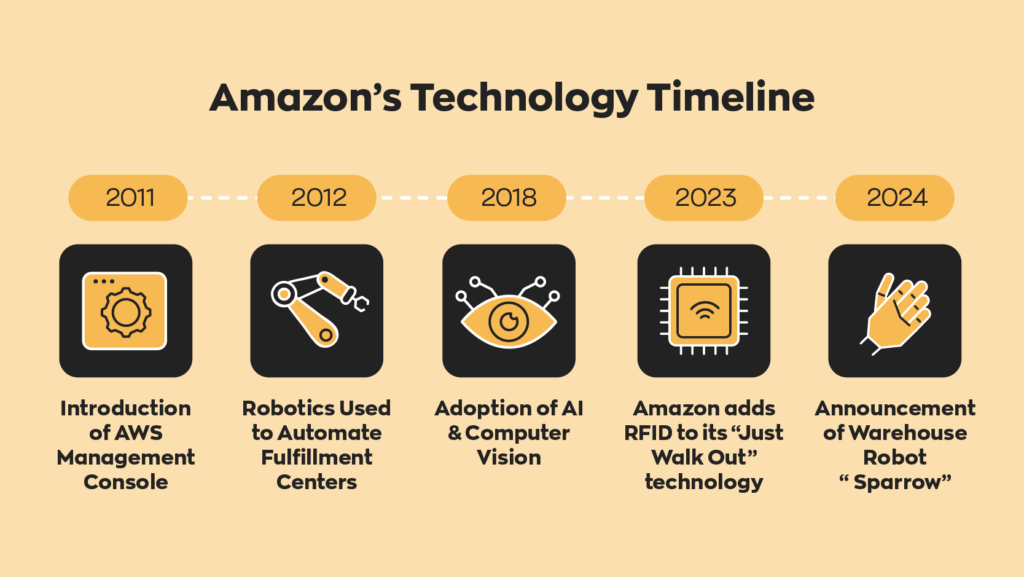

Some companies have already shifted from manual inventory control to systems run with the help of computer vision technology. For example, Amazon began exploring computer vision to improve logistics in the early 2010s. This technology lets them see likely stockouts before they occur, find differences between their inventory counts and actual levels on the shelves, cut back excess stock, and even use just-in-time inventory management.

How Computer Vision Enhances Inventory Monitoring

Simply put, computer vision uses state-of-the-art cameras and AI to check inventory levels automatically. Many experts believe this exciting technology will change how supply chain management operates, so it should come as no surprise that Amazon is leading the charge.

These computer vision systems have machine learning functions and use image recognition software to recognize products on shelves. They then track the movement of those products by continuously taking pictures one after another and noting changes. This enables businesses to regulate inventory levels automatically.

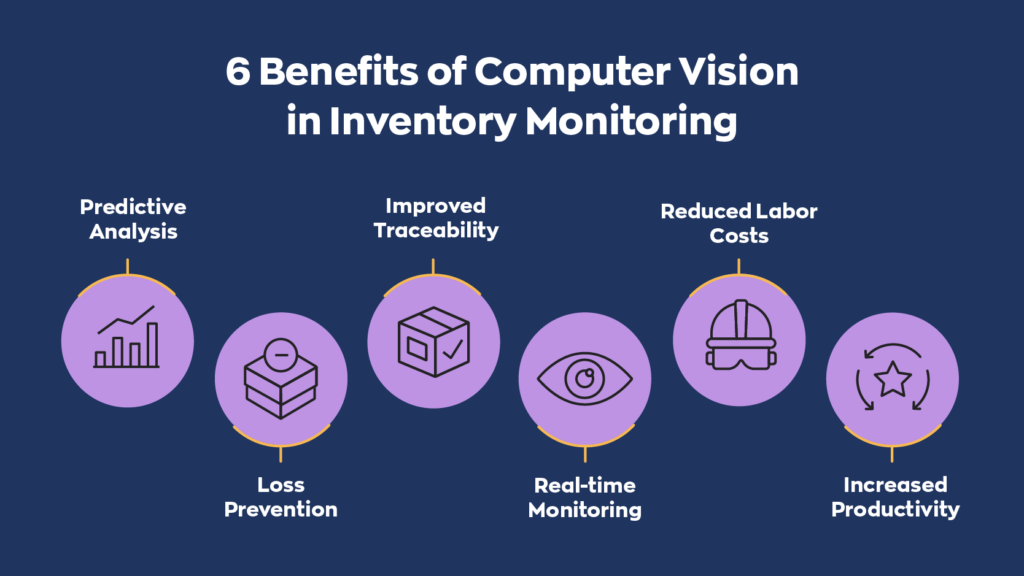

Using computer vision, companies can quite literally have complete inventory visibility. They can detect trends, avoid overaccumulation of stock, and help demand forecasting. These are very flexible systems, able to track thousands of products simultaneously at numerous locations.

The good news is computer vision solutions are becoming cheaper and more accessible. They make it easy for businesses of any size to reorganize operations, reduce costs, and increase customer satisfaction. By applying AI and automation, firms can free themselves up to pursue mission-critical business tasks that spur growth instead of wasting their time on manual monitoring.

What you need to get started

Before diving into the world of computer vision, you’ll need one major prerequisite to get the most out of this new system: an inventory management system with an integrated barcoding system, like our software inFlow.

We know that barcodes are one of the most powerful tools for inventory management, so we’ve spent a lot of time polishing our barcode functionality. With inFlow, you can create, print, and scan barcodes inside the app to quickly fulfill orders, adjust stock, and more!

Without a functioning barcode system, the cameras would have nothing to scan and connect to inventory.

Implementing Computer Vision for Inventory Management

If you’re thinking of implementing computer vision into your inventory management, there are some things you’ll need to consider. We’ve listed a few of them below.

Choosing the Right Cameras

This job isn’t difficult, but it will take some time and research to find cameras that will suit your needs. You’ll want small cameras with sufficient resolution to read labels and make out details, as well as wide-angle lenses so they can cover vast areas. Low light conditions may require the use of infrared cameras.

Developing a Monitoring Strategy

Once the cameras are in place, developing an algorithm for monitoring the inventory is the next step. It will require an algorithm that detects when products enter or leave the storage area, reads labels to identify each item, and calculates running totals of all inventory. However, this is no easy task and will necessitate machine learning models trained on hundreds of hours of footage.

Staff Training

Employees involved in inventory management should receive training on how to interact with the computer vision system. This includes understanding the results of the system, interpreting the data, and using the knowledge gained to make better decisions.

Integrating with Existing Systems

Lastly, the existing inventory management software will need to merge with the computer vision technology. This step is the most challenging since most systems don’t support this emerging technology. To get something working with your system, you’ll need to use software that offers its API to its users. This way, developers can create any necessary integrations.

This is why we’ve made the API to our inventory management system inFlow available to all our users, allowing them to customize our software to their needs. Although computer vision for inventory monitoring might not be easy to implement, it can bring tremendous efficiency and cost savings.

Case Studies: Successful Computer Vision Adoption for Supply Chain Visibility

Many companies are using computer vision to manage the inventories of global supply chains. Through AI-equipped cameras and sensors, businesses get timely insight into their stock levels without having to keep warehouses full of excess products while ending up short on what customers want.

Walmart, a retail giant, utilizes computer vision for inventory optimization in its stores. The technology helps monitor product availability, reduce stockouts, and improve the overall shopping experience for customers. Adopting computer vision for inventory monitoring is the latest example of Walmart’s commitment to leveraging technology for operational excellence.

Another example is Sensytec, which invented ” smart tagging ” computer vision for warehouses. Products are tagged with small wireless pieces, which transmit the product’s identity, quantity, and location. Overhead sensors gather this data, package it in the cloud, and display it on a simple dashboard. For warehouse managers, the system provides a sudden realization of what’s coming in and going out, where there are backups, and when they need to restock.

In this age of Amazon and impatient consumers, businesses need almost prophetic visibility across ever-evolving global supply chains. Computer vision is one of the best tools for attaining this visibility.

Wrapping up

To sum up, the future has arrived, and computer vision is revolutionizing warehouse management software as well as the management of supply chains and inventory. Through computer vision and AI, companies can automate the monitoring of their inventory, significantly increasing their efficiency and cutting down on costs and waste. This technology lets companies get accurate information about their stock in real-time, thus aiding them in making decisions as to what they should have on hand to meet demand. With computer vision, tomorrow’s supply chain will be leaner, faster, and more efficient.

Adopting this technology will give companies an operational advantage and a better chance of winning over customers. Computer vision is already starting to revolutionize the efficiency and productivity of inventory management, and things will only get more sophisticated. The future is automated, data-driven, and AI-powered.

0 Comments