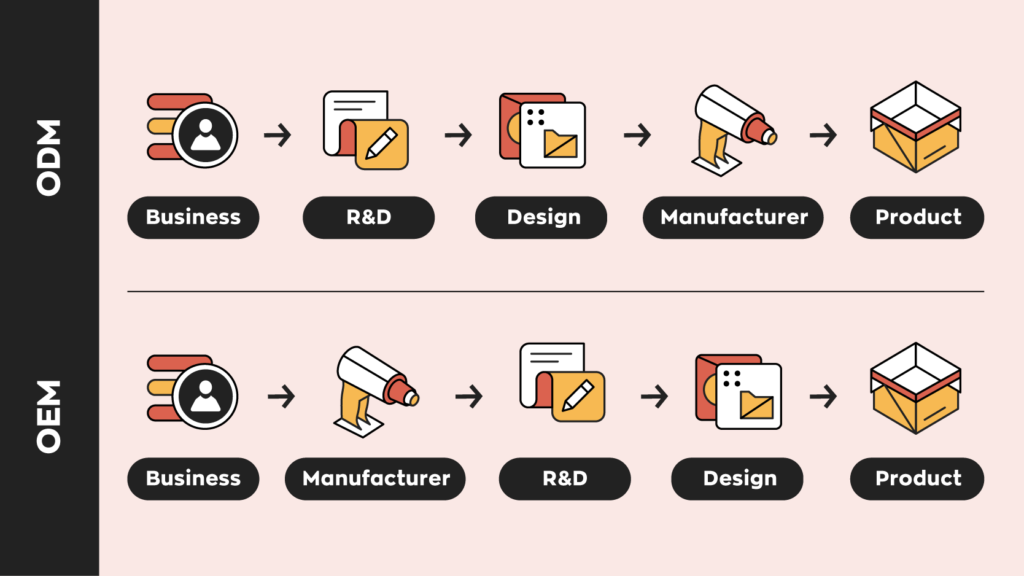

There are a lot of manufacturers out there– many of which you’ll probably never hear of. At the same time, pretty much every manufacturer belongs to one of two categories. They’re either an original equipment manufacturer (OEM) or an original design manufacturer (ODM). So, what’s the difference between OEM vs ODM?

If you’re just starting out on the manufacturing side of things, figuring out which is which can be confusing. And then there’s the question of which one is best for you. Today, we’ll be answering those questions and hopefully giving you an idea of which direction to go.

Before we start, it’s important to note that the term “OEM” differs from industry to industry. For the sake of this article, we’ll be focusing on what it means for the manufacturing side of things.

What does OEM mean?

An OEM would manufacture products based on design specifications given to them by another company. For example, Google researches, designs, and develops its Pixel line of phones and then outsources them to Foxconn for mass production.

There are some businesses, like Samsung, that both design and manufacture their products in-house. However, this is the exception, not the norm. Most businesses don’t have the necessary resources to manage R&D and manufacturing departments at the same time.

As with any other business model, working with an OEM has both pros and cons.

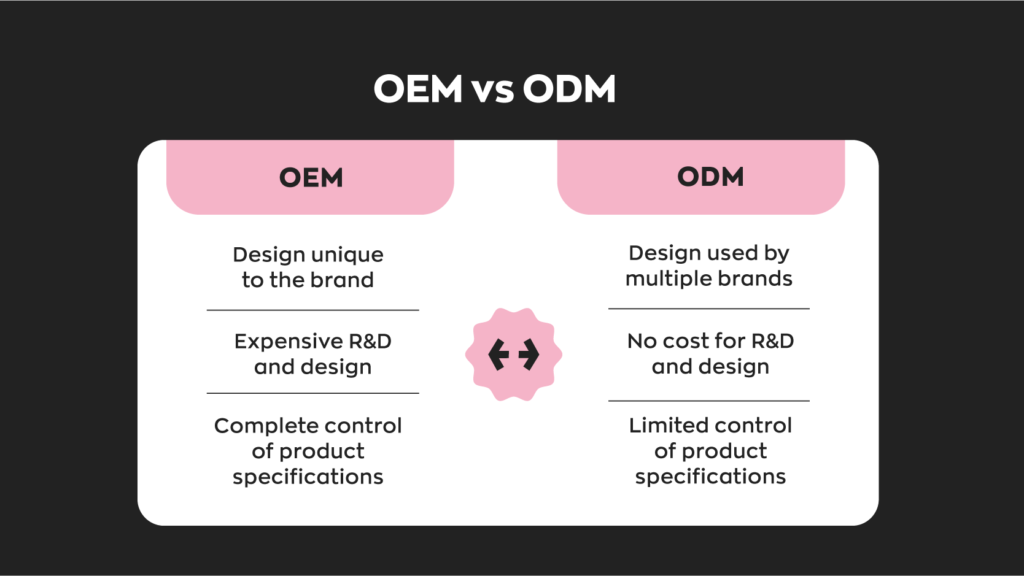

The biggest benefit of working with an OEM vs ODM is that you’re designing your own product. This means that your business owns most (if not all) of the relevant IPs. This results in near-total control of the product.

Designing a product from the ground up also means that your business can tune it to pretty much any specification. This results in far greater flexibility for both the product in question and other products that may rely on it.

Unfortunately, designing your own product from the ground up comes at a cost– literally. The research and development (R&D) phase of product development is notoriously expensive. It takes a lot of time– sometimes years– which, in turn, ends up costing a lot of money. R&D projects are frequently scrapped as well, meaning that there’s no real guarantee on your investment either. Sinking potentially tens of thousands of dollars into a failed project isn’t an attractive prospect for any business. For smaller businesses, it can prove fatal.

For example, Samsung spent $14 billion on R&D in 2014, and that number only rises as time goes on. Samsung also develops a lot of products, but it’s a good example of just how costly R&D can be.

What does ODM mean?

On the other hand, an ODM takes on both the design work and the manufacturing of products and sells them to many different businesses. These businesses will then typically put their branding on the product before selling it. For example, most phone chargers on the market are the same thing. It’s just that individual businesses put their own branding on it.

The biggest benefit of using an ODM vs OEM is that an ODM eliminates the R&D phase entirely. This means that working with an ODM is exponentially cheaper.

Generally speaking, it’s also easier for an ODM to scale its manufacturing process to large sizes. Because they manufacture so much of a specific product, it costs less to manufacture, which results in a lower price. On the other hand, working with an ODM has its own fair share of costs as well. Some of these costs are more abstract, meaning that it can be harder to tell what the “real” cost is.

Working with an ODM means that there’s a good chance that you’re selling the exact same product as someone else. They just look a bit different from one another, and only on the surface level. This can make it difficult to stand out from other competitors– especially if they offer a lower price. Someone looking for a new phone charger isn’t going to care about the brand– they just want the cheapest one available.

This can result in a handful of other issues. You may have to keep track of competitors and re-evaluate your prices– the cost of which adds up over time. On a more abstract level, this could harm brand identity, which carries its own negative implications.

OEM vs ODM: which should you use?

Something we like to say a lot is that every business has different needs, and it remains true for the OEM vs ODM debate. At the end of the day, we can’t tell you whether you should work with an OEM vs ODM. You’ll have to figure out what makes the most sense for your situation. Still, we can offer some (very) basic rules to keep in mind.

- Work with an OEM if you can afford the short-term cost. Designing a product from the ground up is expensive. It’s also not uncommon for companies to scrap R&D projects. If you’re not absolutely sure you can afford the short-term cost– or the possibility of failure– avoid it.

- Work with an OEM if you need control over the product. The R&D phase makes working with an OEM expensive, but the upside is it gives you unparalleled control over specifications. Some products are really important to a business. It’s best to control as many parts of them as possible, and ODMs just don’t offer that level of control.

- Work with an ODM for “generic” products or components. OEMs offer a high level of control and customization, but sometimes there’s simply no need for that. In these instances, it’s best to save time and money and buy from an ODM.

There are also some abstract concepts to consider. Considering the popularity of ecommerce platforms, there are more and more businesses being created than ever. Creating a visual design that sets you apart from the competition is useful but requires the control of an OEM.

OEM vs ODM: final thoughts

At the end of the day, choosing between working with an OEM vs ODM relies heavily on resource consumption. And even if you do have the resources to work with an OEM, sometimes the resource consumption just isn’t worth it.

Keep in mind that using an OEM doesn’t mean you can’t use an ODM (and vice versa). Think about the last time you bought a phone. It probably included a generic charger, right? The phone itself was probably made by an OEM, while the charger was probably purchased from an ODM.

Look at OEMs as an investment. If there’s no clear path to getting a return on your investment, you’re probably better off working with an ODM.

0 Comments