There’s a lot of business essentials that go on behind the scenes. As a consumer, it’s easy to think retailers indiscriminately place products on the shelf. But the truth is far from that. Distribution management is an essential part of maximizing profits and can be the difference between breaking even and going under.

There’s a lot to go over today: what distribution management actually is, how it affects your business, and why proper distribution management software is important. So, Be sure to stick around until the end!

What is distribution management?

Before getting into what distribution management is, it’s important to understand what a distributor is. In the context of the business industry, a distributor is an entity that supplies products to retailers and wholesalers. Retailers and wholesalers then sell those products for profit.

Working off of this knowledge, distribution management is the process of overseeing and organizing the movement of goods from distributors from one party to the other. It may sound simple, but it’s actually rather complicated– and very important.

Broadly speaking, most distribution can be broken down into wholesalers, distributors, brick-and-mortar retailers, and ecommerce shops.

Wholesalers

Wholesalers are the entities that sell their products to retailers in the first place. Instead of selling to consumers little by little, they sell their products to other businesses in bulk. These businesses then go on to sell these products to consumers.

Distributor

This may sound like a repeat of the above information, but the context is slightly different. A distributor is generally a business that manufactures their own product and then distributes it to approved sellers. The best example of this is the automotive industry. Manufacturers like Ford produce vehicles in bulk and then ship them off to approved auto retailers across the globe.

Brick-and-mortar retailers

Retailers (like Wal-Mart, Target, and so on) purchase goods from suppliers. They then sell to consumers at a higher price to turn a profit. This would mark the end of a distribution channel.

Ecommerce shops

While the newest addition, ecommerce has proven to be both disruptive and wildly successful. Amazon remains one of the single most popular shopping platforms, and other platforms like Shopify are also gaining traction. The ecommerce space is characterized by its virtual presentation rather than the traditional brick-and-mortar locations.

What are the different types of distribution channels?

Distribution channels are the pathways in which goods travel from production all the way into the hands of consumers. Their process varies slightly from method to method, but the goal and end result are always the same. Make products and goods accessible to consumers at the right time and place.

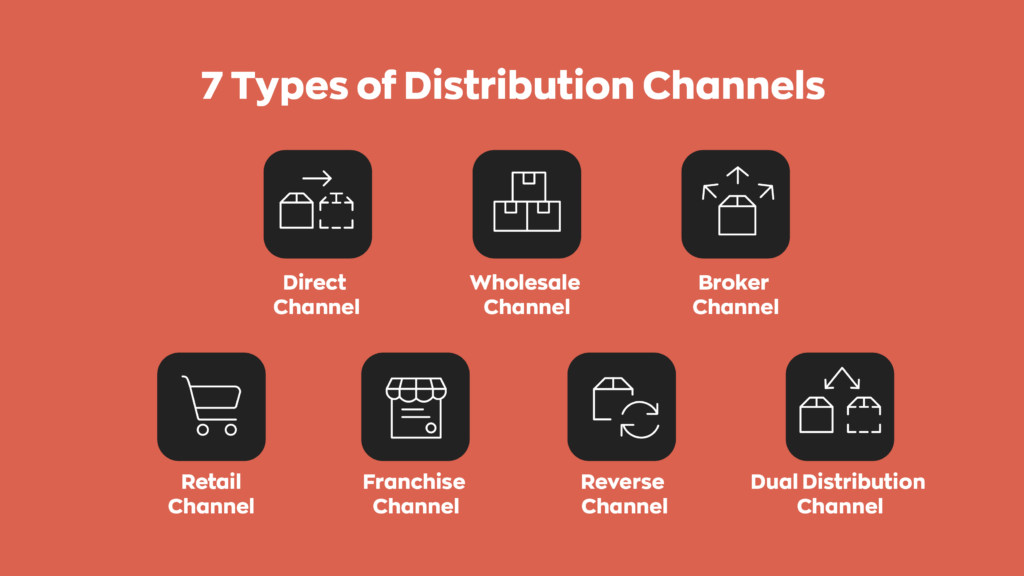

There are several different types of distribution channels which include:

- Direct Channel – Also referred to as zero-level channel, involves selling directly to your customers. An example of direct channel distribution would be a farmer’s market or online store through your website.

- Wholesale Channel – As mentioned above, wholesalers will buy large quantities of products from a manufacturer and break those products down into smaller shipments to then sell to retailers.

- Broker Channel – This type of channel relies on an intermediary to facilitate a transaction between the manufacturer and the supplier. The agent or broker would take a small commission for the transaction but would never take ownership of the goods.

- Retail Channel – Whether in physical stores or online shops, a retailer will buy products from wholesalers or manufacturers and then sell those products to consumers for a profit.

- Franchise Channel – These channels are unique in that they allow retailers to have exclusive rights to certain products. Think of something like McDonald’s. While each store location is owned by an individual, they are all within the same distribution network, ensuring every location is given the same products.

- Reverse Channel – This channel has seen a gain in popularity as people have become more focused on sustainability. It involves a model that allows customers to return their old products to be reused or recycled. An example of this would be Apple’s trade-in program.

- Dual Distribution Channel – A dual distribution channel is becoming more common with the rise of ecommerce. In this model, a company is using more than one way to distribute its products. For instance, if you sold your products directly to customers through an online store but also sold them to wholesalers.

Why is distribution management important?

The most obvious benefit of a proper distribution management system is that it directly increases profit. When implemented correctly, distribution management eliminates inefficiencies and waste. Not just physical waste like fuel but wasted manpower as well. In some cases, this allows businesses to redistribute resources elsewhere. In turn, this process directly lowers operating costs, resulting in greater profit.

Distribution management is also a great way to cut down on shipping costs. This can be difficult to quantify immediately because of the many variables that go into shipping costs, such as weight, type of product, and so on. But proper distribution management will undoubtedly cut down on some of these areas of spending.

Challenges of distribution management

As you’ve likely surmised by now, a proper distribution management system relies heavily on distribution service. Which, unfortunately, are often volatile. Now, to be clear, this isn’t the fault of the companies who manage supply lines. Their profits also rely on timely shipping and product readiness! But they also rely on other service networks, and these networks are susceptible to many different things.

On a large scale, distribution management is affected by both natural and human-caused events. COVID-19, for example, was a near-unprecedented natural disaster. Authorities considered it a global health crisis, and many industries were forced to grind to a halt as a result.

As for human-caused events, think riots, strikes, or even labor shortages. For example, the recent UPS strike threat would have halted deliveries entirely until both parties came to an agreement. These disruptions can also be caused by things like vehicle mismanagement or breakdowns.

On a smaller scale, the products themselves are subject to several factors, both external and internal. We’ve rounded up some of these factors below.

Perishability

Not all products stay good forever, so keeping track of how long something will keep is essential. You can’t (and shouldn’t!) sell a consumer a defunct product, or worse, something past its expiration date.

This factor becomes more complicated to account for when more products are in the mix. For example, a batch of fruit has a shorter lifespan than a bag of chips. More factors mean more things to account for.

Sales trends

The unfortunate truth is that outside essentials like food, only some products consistently sell year-round. In extreme cases, something could sell out one day and not sell at all the next.

Shipping optimizations

This is a very broad term, and it’s arguably the single greatest challenge. Do you ship two products to the same area and distribute them from there? Or do you ship them to two locations closer to their destinations? Which is cheaper? Which is faster? There’s a lot of questions, and it’s not something that someone can figure out by hand– more on that later.

Distribution management tips and tricks

We say this a lot because it’s worth repeating: every business has different needs. That’s especially true here, where one business probably has a vastly different product catalog from another. As a result, they have different shipping needs. Even with all those differences, though, there are some foundations that remain true from business to business.

Become as efficient as possible

At the end of the day, efficiency is key. It reduces overhead costs, can help fortify other areas, and positively impacts your reputation. Unfortunately, there’s no easy road to maximum efficiency. It requires data and long-term knowledge. It also has unquantifiable factors to consider, like employee morale. This can be as little as refining manpower distribution and as complicated as calculating delivery distribution efficiency.

Use sales forecasts

Sales can be fickle, but that doesn’t mean they’re impossible to predict. Market experts and financial analysts can create sales forecasts. These reports help businesses estimate their sales numbers and allow them to prepare accordingly.

Build business relationships

It’s no secret that businesses are number-oriented. Because of that, it’s easy to forget that the business industry is also a very human one. Going out of your way to build business relationships with services you rely on can be worth it. They may prioritize your orders over others, which can sometimes be the deciding factor.

Use distribution management software

These things can be very difficult to figure out. Not just distribution management– financial information can be challenging to make sense of. It’s why more and more businesses are turning to distribution management software. It helps track all the comings and goings of your products and can generate financial reports with the click of a button.

Software like inFlow also offers a variety of other functionalities, ranging from inventory management to manufacturing tracking. Distributors can also promote their products with their own B2B showroom so their customers can go and place orders directly. The end result is a central system that provides a foundation for everything you need.

Wrapping up

Distribution management is an important but often overlooked part of business. Because of how it affects your inventory and sales, it can be the deciding factor in breaking even, making a profit, or going under. Unfortunately, it’s a complicated process that requires a lot of maintenance.

The volatility of supply lines means that what was true yesterday might not be true today. As a result, you’ll have to carefully monitor your distribution management and ensure nothing major is around the corner.

0 Comments