A business that offers some sort of field service has a lot of things to keep track of. Allocation of labor and materials, cost of materials, and invoices, just to name a few. It’s tricky business! These shifting variables are a large part of the reason that field service management software has become more common.

So: what is field service management software? How does it help the field service management process? What does it track? Can you make do without it? What other business tools can you use in conjunction with it?

Let’s Dig in!

What is field service management software?

Before we answer what field service management software is let’s first define field service. Put simply, if your business provides on-site services, whether at the client’s home or in another area, your business qualifies as a field service provider (FSP). The term itself may sound fancy, but it really just means that you provide a service at the customer’s location. Some examples of field service providers include plumbers, general contractors, electricians, etc.

Field service management software is a piece of tech that helps manage the day-to-day logistics of such operations. This can include tracking assets such as tools and machinery or components used on the job site.

Why is field service management software important?

Even if the service that you offer is straightforward, there’s a lot that goes on in the background. For example, let’s pretend that you run a business that offers electrical repairs. Different technicians may have different skill sets. They may also have different certifications, limiting what they can legally work on. This one factor alone introduces a handful of factors to consider.

You’ll have to manage which technicians respond to which calls while keeping their separate certifications in mind. It also means keeping track of the time logged at each worksite as well as the materials used at each worksite.

And because different worksites require different materials, the cost of materials will vary wildly from site to site. All this stems from just one workplace variable. The bigger things get, the more things you’ll have to keep track of. This is also just one example. Other field services that require more technical experience might have a lot of factors they need to keep track of.

How does field service management software help?

Before the introduction and subsequent adoption of field service management software, field service managers would keep track of things the old-fashioned way: phone calls, pen and paper, and a lot of paperwork and spreadsheets. It was time-consuming and required a lot of back and forth. It was also tedious, and because of that, errors were common.

Field service management software aims to solve these issues by doing two things. First, it seeks to automate as many repetitive tasks as possible. Things like tracking inventory through purchase and sales orders and keeping tabs on assets are done easily with a few taps of a button, which reduces the possibility of human error.

It also aims to improve communication across the board. By acting as a communication hub of sorts, and in tandem with automation, a lot of the back-and-forth gets cut out. This makes it easier for field service managers to assign worksites, send invoices, and just saves time in general.

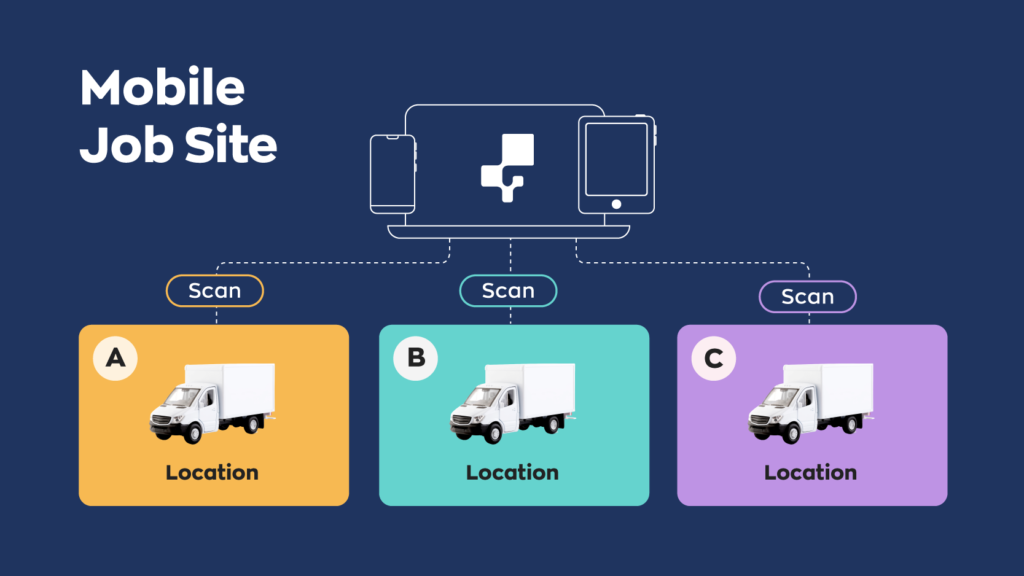

For example, let’s say you run a general contracting business and have multiple sub-contractors working for you. Each one of these sub-contractors has their own truck with tools and materials they use on the job site. With field service management software, you can set up each one of those trucks as a location, and the workers can scan and remove materials from inventory as they use them. This gives you full traceability and transparency into what you have and where it is.

Lastly– but perhaps most importantly– field service management software helps with the financial side of things, too. It tracks materials costs by job site, making the invoicing process much easier. Instead of tracking the cost of materials manually.

Can you go without it?

Businesses can operate without field service management software, but they really shouldn’t. Even in the digital age, record-keeping is an important part of running a business. If you don’t have a way of recording these things digitally, that means paperwork. Not only is paperwork tedious and time-consuming, it’s also much more difficult to access than a cloud-based system.

Instead of accessing important documents from your phone or computer and being able to search for them electronically, you’ll have to make multiple copies of documents and spend time organizing and rewriting them each time a change occurs.

While there’s an immediate cost for implementation, the time saved quickly makes up for it.

How can other systems help?

It’s not like field service management software is a closed system, either. It can work with other pre-existing systems to streamline your work process even more. One example of this is with barcodes. We tend to think of barcodes as a one-dimensional tool. Scan a barcode, get a price.

In reality, they’re powerful tools that can you can encode with many different meanings or instructions. For instance, field services generally use a lot of specialized equipment. It’s expensive, heavy, and because of that, there’s generally only a few units available at any given time.

Keeping track of this sort of equipment is difficult, but barcoding– in conjunction with field service management software– can help. Putting a unique barcode on a piece of equipment means that whenever someone scans it, you’ll have a record of exactly where it is.

You can use this same method to track materials and equipment used at specific worksites. Instead of tracking materials manually or by hand, you can barcode the components and scan them as you use them. That way, you’ll have a record of the components as they come and go. This generates an accurate count of materials and equipment used each day– without the need for manual inputs.

On top of that, even between different worksites, the scope of work tends to be similar. Keeping track of what equipment was used can give workers an idea of what tools they need for the job. This helps eliminate more of the back and forth, ensuring that jobs are being completed as soon as possible. Unique barcodes can also be created for each individual job site, creating accurate records of everything used.

How can inFlow help?

An important part of running a business is putting as many things as possible into one place. inFlow offers a perpetual inventory management system that’s been integrated with the field service management side of things. You’ll always know when and where something was pulled off the shelf, and by who.

On top of that, inFlow tracks material costs, which makes creating an invoice when the job’s done a piece of cake. Considering its affordability, it’s the perfect field service management software for small businesses.

0 Comments