There’s a lot of reasons to love solar power. It helps consumers lower their power bills while reducing carbon emissions. For solar installers, that makes this an opportune time to scale up in order to meet the rising demand. However, as with any industry, some challenges come with expanding. Inventory management for solar companies is notoriously difficult for a variety of reasons, and even a slight error can be crippling.

But what makes inventory management for solar companies more difficult? And how can solar installers make things easier?

Solar inventory management challenges

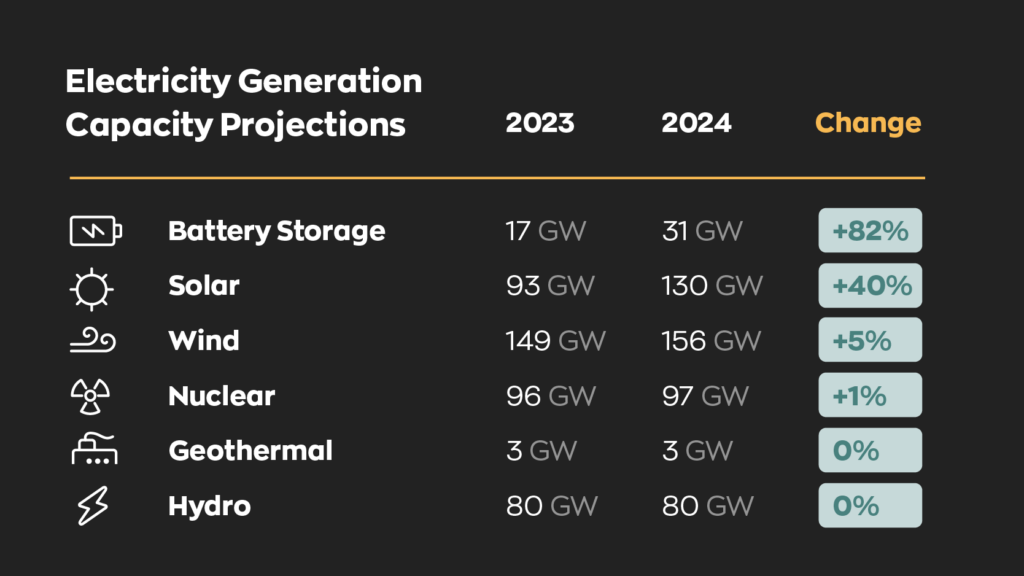

Experts predict that the renewable energy industry will continue to grow in 2024. This means many solar installers will experience rapid growth in the coming years, along with all the challenges that come with that growth.

Now, to be clear, some of the challenges are not unique to solar installers. Truthfully, many inventory management challenges don’t discriminate between industries. An issue in one industry will almost certainly be an issue in another, but the severity of the problem for solar inventory management and how you handle it may differ.

Here are some things to consider when dealing with inventory management for solar companies.

Expensive inventory

Solar installers offer much more than just physical goods, but at the end of the day, customers are paying for a working solar system. Solar panels are an essential part of that system, and high-quality ones tend to be expensive. That on its own isn’t an issue—there’s a lot of expensive products out there— but the real problem is that they’re also fragile.

Like any business that deals with physical goods, solar installers will inevitably experience shrinkage. This can be caused by several things, such as damaged components, defects, or lost items. As such, most businesses plan for a certain margin of error, but the premium price of solar panels makes shrinkage much more damaging.

Proper inventory management for solar companies means tracking expensive components to ensure you know exactly what you have across multiple job sites. It will also ensure you only keep what you need on hand and don’t overstock. After all, hanging on to expensive excess inventory is a liability every business should avoid.

Various components and tools to track

Of course, solar panels aren’t the only thing to worry about. Many other smaller parts are necessary for installation. They’re not as expensive as the panels themselves, but they’re no less critical and much easier to lose track of. The necessary components also change slightly depending on the work site, which can make locating them even more difficult.

Different job sites will require not only different components but also a different set of tools. Solar installers may need different equipment depending on the existing architecture. The equipment could also differ according to the scope of work.

Shifts in demand

Seasonal demand is commonplace across most markets, but the solar industry is affected by more external factors than most. Alongside state and federal legislation, even broad factors like climate change can affect demand for solar.

This necessitates careful consideration of the future. It’s a bit of a balancing act. Purchasing too much inventory ties up capital in storage, but too little can slow down business. Inventory management for solar companies is generally more precarious because of high inventory costs.

Special storage requirements

Solar panels are large; more surface area means more solar power, which means more savings. But couple this with their fragility, and you’ve got a high-value product that’s difficult to store—not a great combination. It may be necessary to rent specialized warehouse space not only to ensure you have the required space but also to keep your high-value inventory safe.

Routing difficulties

Inventory management for solar companies will experience many of the same issues other field service workers come across. One such problem is overseeing the delivery of necessary inventory to the proper locations. If you store your resources in different warehouses or locations, incorrect routing can slow everything down.

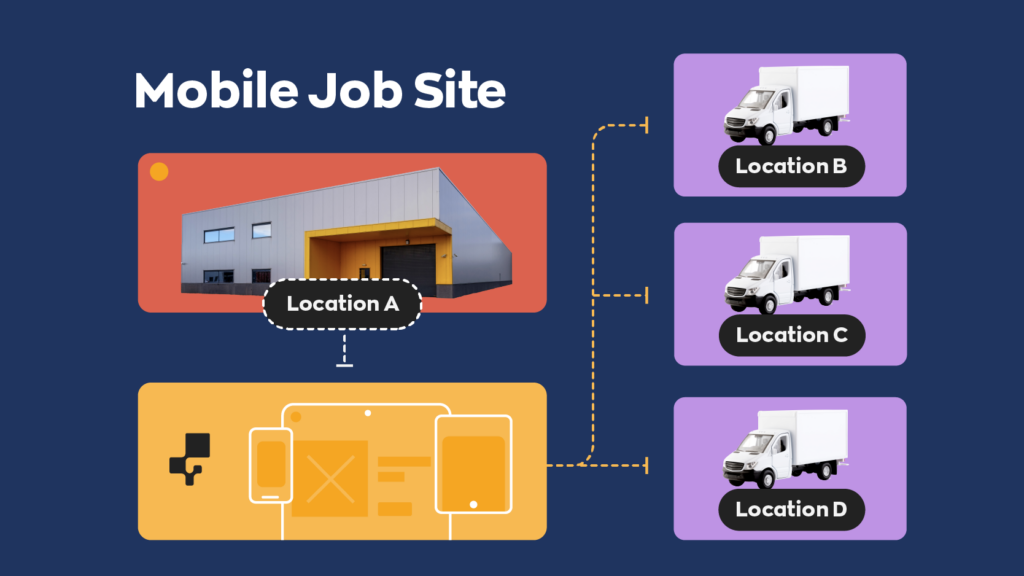

Impractical inventory routing is a big reason we recommend solar companies switch to a mobile job site workflow. This method turns service trucks into mini-warehouses on wheels so you can effectively track your components on the go across multiple job site locations. Of course, you’ll need cloud-based inventory software for this workflow to function (we’ll get more into this later).

Inventory management for solar companies

It’s important to remember that it’s nearly impossible to eliminate inventory-related difficulties entirely. If running a solar installation business were smooth sailing all the time, everyone would do it. Still, alleviating these issues as much as possible is important to maximize profits. Here are some possible solutions.

Commit to proper solar inventory management software

The most straightforward way to keep track of everything is to commit to proper inventory management software. Cloud-based field management software, like inFlow, tracks your inventory and assets in real-time, ensuring everyone knows where everything is at all times.

Our software makes inventory management for solar companies easier than ever. You can set reorder points for all your products so you’ll always have the perfect amount of stock. Our reporting features make it easy to forecast demand. We even have a built-in barcoding system to help speed up your workflow while increasing accuracy!

Implement just-in-time inventory

There are also many different inventory management methods. For solar installers specifically, just-in-time (JIT) makes a lot of sense. It’s a method that prioritizes having the absolute minimum amount of inventory. It does this by using data and working closely with suppliers to receive products as they’re needed. For example, if your company has a job in a week, the products won’t arrive until shortly before work starts. Because solar companies work with expensive components, JIT helps them maximize cash flow.

Store inventory in multiple locations

In some instances, splitting materials and components into different warehouses saves money. Throwing everything into the same warehouse can be tempting, but that’s not always the most efficient. It may be better to rent space that specializes in storing solar panels, and store other components elsewhere.

Another option, as we mentioned earlier, would be adopting a mobile job site workflow. This would help your company stay agile and avoid the extra overhead it would cost to rent more warehouse space. However, inventory management for solar companies will require at least some physical warehouse for storage due to the size of solar panels.

Invest in data analytics

As with anything, inventory management for solar companies can yield quite a bit of data. This data is helpful for a variety of applications. For example, long-term data collection is a crucial part of demand forecasting. Predicting sales is especially vital when working with high-cost materials like the requisite solar panels.

This is yet another area where inFlow can help. Our software lets you pull all kinds of reports to help you forecast your demand.

Wrapping up

When it comes down to it, the purpose of a business is to make money. Businesses in the solar industry are no different. However, increasing revenue and maintaining a healthy cash flow can be difficult because of the high component cost. Inventory management for solar companies ideally focuses on keeping inventory as low as possible to maintain healthy capital.

0 Comments