Just-in-time systems have been popular since their invention in the 1950s. But, from the pandemic to transport issues, recent events show just how precarious supply chains are. It’s time to think about whether just-in-time inventory management methods are still the right option.

Today, we’re delving into just-in-time inventory management: what it is and what the future holds. We also briefly talked about just-in-time inventory in our new podcast. You can watch the short clip below.

What is just-in-time (JIT)?

Just-in-time is a form of management commonly used in retail and manufacturing. The idea is to hold (or make) only the stock that you need immediately. Items arrive as you need them – just in time – rather than as bulk orders that need to be held until they sell later on.

To do this, a retailer might only place an order with a manufacturer when the customer buys from them. A manufacturer may endeavor to only make parts on demand. As JIT is a methodology rather than a system in itself, businesses decide what works best for them and implement models accordingly. For instance, forecasting for a very short period and ordering only that stock.

A history of just-in-time inventory management

Just-in-time has its origins in manufacturing. It is similar to, and often used as a synonym for, the lean manufacturing method, which stems back to a Toyota engineer named Taiichi Ohno in the 1950s.

He developed a method in which parts were made just as they were needed and delivered to the production line just before their use. The engineer also spoke of the ‘seven wastes’, which cost businesses money unnecessarily, which are:

- Overproduction

- Waiting time

- Transportation

- Processing

- Motion

- Defects

- Inventory waste

Inventory waste refers to carrying excess stock to be sold or parts to be used that take up space and cost the business money. This is a key reason many businesses opt for just-in-time inventory management today.

You can find out more about the origins of the JIT system for manufacturing here.

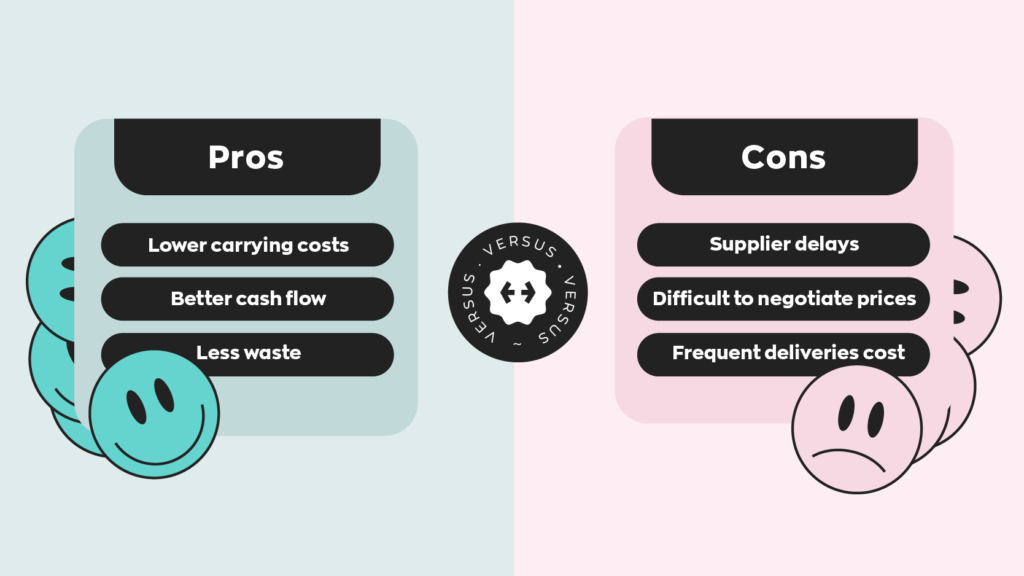

The advantages and disadvantages of JIT for inventory

Like any method, just-in-time inventory management has its pros and cons. Below, we’ve listed some of the main factors to take into consideration.

Advantages

Lower carrying costs

As mentioned above, holding stock comes with costs. Some of these costs are evident, like the cost of the capital invested in the stock or paying for the space to store the items. But there are other factors to take into account too, such as shrinkage (for example, damaged goods).

Using a JIT system usually means storing less stock, which can combat these expenses.

Take a look at how to calculate carrying costs.

Better cash flow

Pre-ordering large quantities of stock can cause cash flow issues for retailers. When your money isn’t tied up in inventory, it can be invested in other areas or used to expand the current range.

Less waste

Imagine you need to order hats for summer. If you order items based on, for example, quarterly forecasts, your business may find itself with too much or too little stock at the end of the period should that style no longer be in fashion, or if the weather isn’t warm enough.

Ordering just what you need, when you need it, gives the business the chance to stay adaptable and reduce wastage.

Disadvantages

Supplier delays

When you order inventory, you depend on your supplier delivering when they say they will. Delays could cause stockouts, especially if you’re ordering what you need just as you need it.

Knowing where your products come from might help you create a more stable supply chain. However, only 2% of companies reportedly have visibility into their supply base beyond the second tier. This is something to bear in mind with JIT systems.

Difficult to negotiate prices

The just-in-time inventory model doesn’t allow for buying in bulk, which might mean saying goodbye to much-loved discounts. Whether or not this is an issue will depend on whether it is truly more cost-effective to receive the discount and carry the extra stock.

In the case of unprecedented demand, businesses can also face difficulties negotiating better prices for last-minute orders. They also may not be able to wait for prices to drop if they spike.

Frequent deliveries cost

Ordering, receiving, and processing inventory costs money. Consider administration and delivery fees when deciding whether your JIT system is saving the business money.

Consider what works for your business

Some of the above factors will affect some businesses more than others. For example, you may be more prone to experiencing delays if using international suppliers, or more dependent on bulk-buy discounts if you sell fast-moving consumer goods. With this in mind, it’s important to evaluate what works for your business.

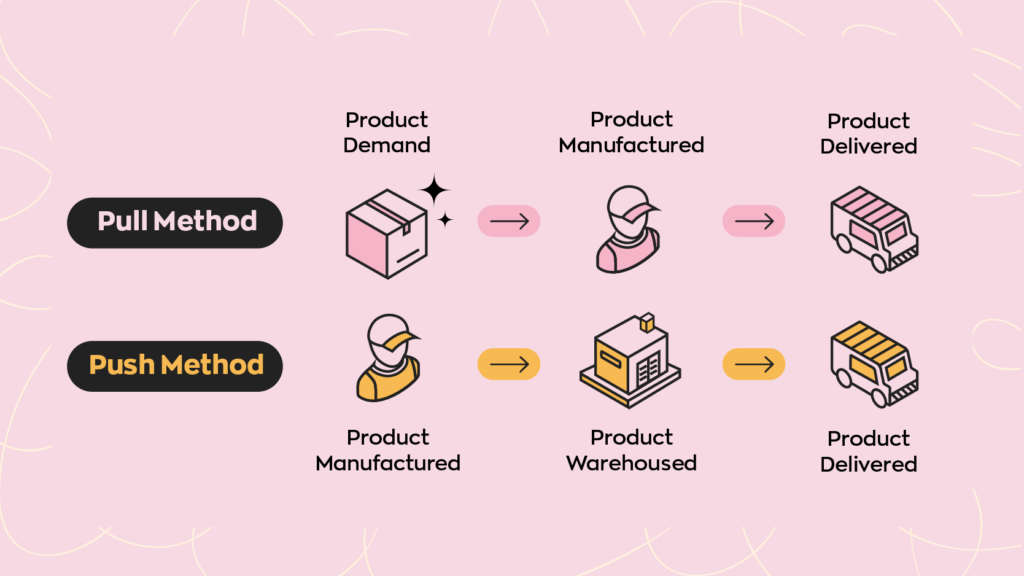

Push vs. pull inventory management methods

When choosing an inventory management method, you may come across the terms ‘push’ and ‘pull’. These aren’t methods of their own so much as ways of categorizing other systems.

A push system uses forecasting to work out inventory needs. The business analyzes sales data from previous periods and orders stock in advance. Usually, this should include enough items to satisfy demand and avoid stockouts.

A pull system keeps an eye on current sales. The business analyzes how products are selling at that time and orders based on demand. Just-in-time inventory is an example of a pull system.

Is just-in-time inventory relevant today?

The last few years have shaken up supply chains around the world. We’ve seen how unpredictable shipments can be. When one part of the chain experiences a setback, everyone is affected.

It’s not just about the pandemic, either, we’ve seen natural disasters, transport issues, and the need to reduce carbon emissions. With this in mind, many companies have begun to question whether JIT is still the best methodology for them.

As Nissan CEO Ashwani Gupta explains (via World Economic Forum):

“The just-in-time model is designed for supply-chain efficiencies and economies of scale. The repercussions of an unprecedented crisis like COVID highlight the fragility of our supply-chain model.”

So, which other options can businesses consider?

The just-in-case alternative

The just-in-case (JIC) model involves ordering extra ‘safety’ stock so that there are always items on hand if needed. That way, if there’s an issue with a delivery or unprecedented demand, you have items on hand for customers.

You can read more about safety stock on our reorder point calculation page.

When it comes to JIC vs JIT systems, the key is determining what works for you. As PWC explains, businesses can even balance the two systems, taking a hybrid approach. For example, you might ensure you have a backup supply of inventory for high-value customers, whether that’s alternative options or safety stock.

The importance of having the right systems in place

Choosing the right inventory management methods can make your business more efficient. That doesn’t stop at ordering the right items at the right time. From finding the best warehouse order picking method to implementing barcoding, analyzing what works best for your company can help you save time and boost profits.

0 Comments