Key takeaways

- MOQ (Minimum Order Quantity) is the minimum number of units a business is willing to sell per order to ensure a certain profit margin with each sale by covering the cost of goods sold (COGS).

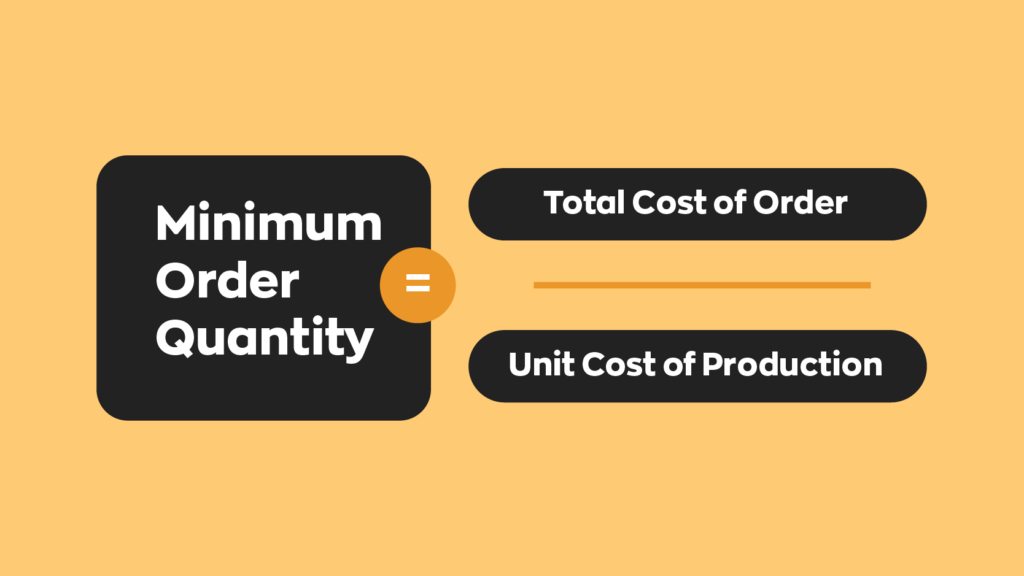

- Formula: Minimum Order Quantity = Total Cost of Order / Unit Cost of Production

- MOQ for manufacturers dictates the minimum quantity for a production run to be profitable.

- Minimum order quantity is not suitable for every business, especially direct-to-consumer retailers or expensive, low-demand products like appliances.

- Some factors that affect MOQ include demand, break-even point, and production capacity.

- There are four types of MOQ; low, high, simple and complex.

- Software solutions can assist in calculating accurate MOQs.

Running a business might seem simple. Sell your product, make a profit. Easy, right? Unfortunately, reality isn’t quite that simple. Both wholesalers and manufacturers need to consider the cost of goods sold (COGS) when selling their products, and smaller orders tend to result in higher COGS. If a product’s COGS is $15, and you sell it for $14, you’re taking a $1 loss each sale. This is, in part, the reason that businesses may set a minimum order quantity or MOQ.

But what is the MOQ meaning, and how does it help businesses remain profitable? We’ll be going over all of that and more today.

Minimum order quantity (MOQ) meaning

As we said above, MOQ stands for minimum order quantity. As the term suggests, it’s the minimum number of units a business is willing to sell per order. For example, if a wholesaler sets an MOQ of ten units, their buyers must purchase at least ten per order.

An important note here is that MOQ and economic order quantity (EOQ) are not the same thing. EOQ represents the ideal amount of product that a business should stock to maximize profits while minimizing costs. We won’t go in-depth about it, but if you want to read more, you can check out our article about EOQ here.

The MOQ meaning changes slightly between businesses and industries. For example, wholesalers tend to sell in bulk already, so for them, MOQ typically refers to the minimum order to receive discount pricing. On the flip side, for retailers, it’s the minimum they purchase per order from suppliers. For manufacturers, it’s the minimum number of units requested in order to begin a production run.

Why is MOQ useful?

We should start by saying minimum order quantities aren’t a useful sales tactic for every business. This is because MOQ’s general purpose is to guarantee a certain profit margin with each sale. Its application may vary from industry to industry (MOQ meaning in manufacturing differs from the MOQ meaning in wholesaling, for example), but its purpose generally remains consistent.

It’s important to note that an MOQ should only be set after careful consideration and a lot of number-crunching. Setting prices even a tad bit too low can have catastrophic effects, especially for businesses with high MOQs.

However, once a business finds the right MOQ at the right price, they guarantee a certain profit with each sale.

For example, let’s say a manufacturer looked at all its operational costs, such as the costs of running a production cycle, picking and packing, shipping, taxes, etc. After this analysis, it concluded that it needs to manufacture at least 500 units in order to make its desired profit from a production cycle. If a manufacturer sets an MOQ of 500 units at $5/unit, it’ll net $2500 with each sale at a minimum.

When to avoid implementing minimum order quantity

Of course, no business model is one size fits all. While there are exceptions, MOQ tends to work best with high-volume, low-cost products. It’s also important to note that it’s more common for manufacturers, distributors, or wholesalers to have a minimum order quantity.

Typically, direct-to-consumer retailers don’t use MOQs. MOQ can sometimes be confused with order minimums used by ecommerce retailers, but these two things are different.

For example, implementing a MOQ for something like washing machines is probably a bad idea if you’re a retailer. They’re expensive, and consumers typically only need one. An occasional bulk order might come in, but not often.

On the other hand, a smartphone manufacturer might implement a minimum order quantity for wholesalers or retailers. While still expensive, smartphones are still cheaper than washing machines—and almost everyone uses one daily.

A good rule of thumb is that minimum order quantity is ideal for high-demand, easy-to-sell products.

MOQ formula

So far, we’ve explored the MOQ meaning. So– how do you calculate it?

You could plug a few numbers into an equation, but finding the ideal MOQ is a complex, nuanced undertaking that requires an intimate understanding of a business. Fortunately, these days, robust wholesale software can collect data, crunch the numbers, and help you implement the ideal MOQ.

However, if you’re looking for an oversimplified formula to get you started the MOQ formula would look a little something like this:

That said, it’s still important to understand what factors affect MOQ. Generally, three main factors directly impact minimum order quantity.

- Demand – At the end of the day, businesses survive according to demand. No demand means no sales, which means no revenue.

- Break-even point – The break-even point is exactly what it sounds like. It’s the per-unit price that yields no profit and incurs no loss. Knowing this number keeps businesses from setting the MOQ too low. Make sure to factor in overhead costs like storage.

- Production capacity – Even if a product is in high demand, it means nothing if no one can manufacture it. Unfortunately, production capacity can be volatile. It’s affected by many factors, such as material scarcity, supply chain disruptions, and so on.

Different types of minimum order quantity

There’s a few different types of MOQ: high, low, simple, and complex. Though the MOQ meaning might change between each one, their purpose remains the same. Let’s take a closer look at each.

Low minimum order quantity

A low MOQ can range anywhere from 50 units to 250. While setting a low MOQ doesn’t do much to maximize profitability, it results in a low barrier of entry. Customers are more likely to complete– and repeat– their orders.

High minimum order quantity

The inverse of low MOQ. Like before, this number can vary greatly but usually refers to anything above 500 units. A high MOQ leads to better margins and larger sales figures, but it might decrease the number of sales.

Simple minimum order quantity

A “simple” MOQ means there’s a single condition to the order. Usually, this is the MOQ itself– manufacturers will set a minimum to guarantee a profit. A simple minimum order quantity will be the same for all buyers.

Complex minimum order quantity

A complex MOQ means there’s more than one condition to the order. For example, manufacturers may limit the use of a certain material to a certain amount before accepting the order. This is more common in industries where customization is important.

How inFlow can help you set your MOQ

And there you have it! Now you know all about the MOQ meaning and its different forms. Before you set off to calculate your ideal minimum order quantity, ensure you truly understand your business’s ins and outs. Working with improper numbers and calculations can cause big issues.

We make it easy for inFlow users to calculate their MOQ. Our inventory management software helps you calculate the cost of goods sold and provides detailed sales records. You can use these numbers to help you determine the perfect MOQ for each of your products! So, if you want something to help you find those perfect MOQs, look no further than inFlow!

0 Comments