Key Takeaways

- MRO inventory stands for maintenance, repair, and operations.

- It’s a specific class of inventory that refers to materials and supplies used to keep business operations running.

- MRO inventory is not a part of the final product.

- Properly managing MRO helps a business operate more efficiently and increase profits.

- Poorly managing MRO can cause a loss in profits due to downtime, production issues, and unsafe working conditions.

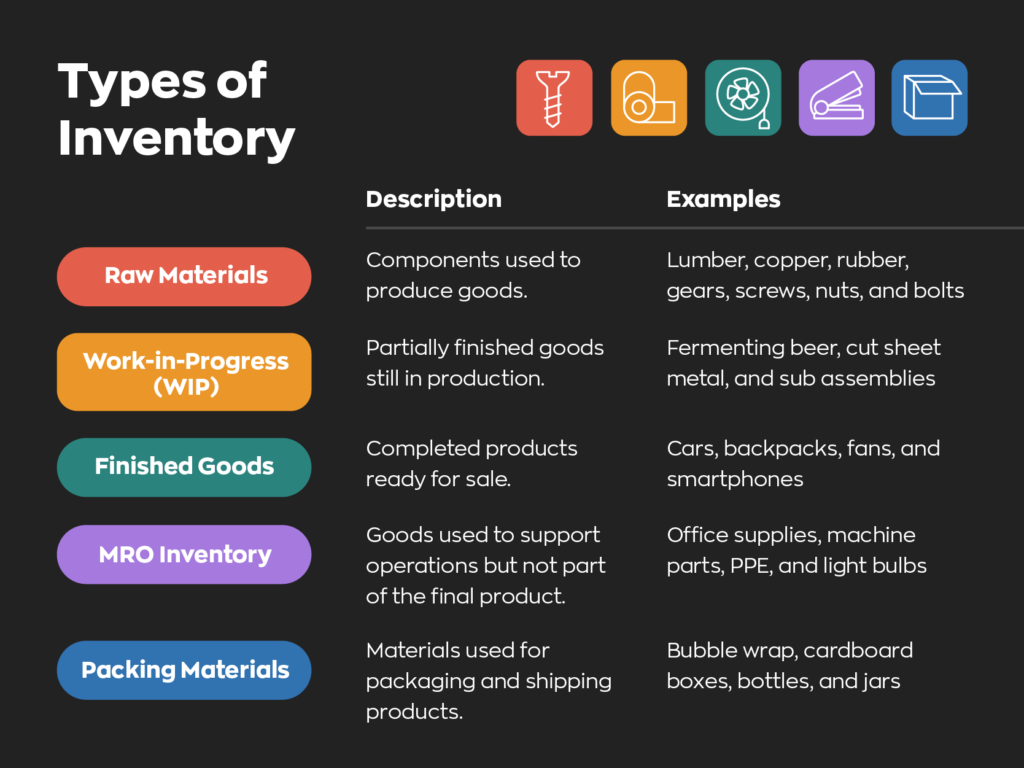

When you’re running a business, you’ll need to manage a lot of different types of inventory. Most companies focus most of their attention on product-related inventory, such as raw materials, components, and finished goods. But there’s another type of inventory that’s just as crucial to keep everything running smoothly: MRO inventory.

MRO inventory (maintenance, repair, and operational), which encompasses supplies, tools, and equipment, plays a crucial role in any business. It ensures that operations stay on schedule and productivity remains as high as possible. So, what is MRO Inventory? What role does it play, and why is it important? And how should businesses manage it? Let’s look at this often-overlooked inventory type in more detail.

What is MRO inventory?

It’s fairly easy to guess what the MRO meaning is. Also called MRO supplies, it refers to inventory a business uses during production. There’s a caveat, though: MRO inventory can’t be part of the final product. Anything used during the production process that becomes a part of the finished product would be considered raw materials or components.

For example, take an electronics manufacturer that specializes in semiconductors. The assembly of the semiconductors requires various metal pieces, silicone, and epoxy. It also requires personal protective equipment (PPE) and tools to assemble the pieces. In this example, the raw materials are the metal pieces, silicone, and epoxy; the PPE and tools are the MRO inventory.

However, MRO inventory doesn’t just relate to things directly used in the production of the semiconductors. A plethora of other things that assist in business operations also fall into this category. For instance, scales, pallet jacks, and machinery would also qualify as MRO inventory.

These items are essential to the production process but absent from the final product. As a result, we can classify these products as MRO supplies.

MRO inventory examples

There are a slew of things that can be considered MRO inventory. It really depends on what type of business you’re running. Manufacturers tend to have more MRO inventory to worry about, but make no mistake; every business has MRO inventory. Here are some common examples of MRO inventory:

- Consumables – Cleaning supplies, light bulbs, and cleaning solutions.

- Maintenance supplies – Lubricants, tools, cleaning equipment, and janitorial supplies.

- Operational supplies – PPE, printer paper, printer ink, staplers, paper clips, and other office supplies

- Repair parts – Motors, gaskets, springs, seals, filters, and any other replacement parts needed for equipment.

Generally speaking, businesses can break down MRO inventory into three categories:

- Production MRO – All parts, tools, and equipment necessary to keep processes running would fall into this category.

- Administrative MRO – This category is for any items used in the day-to-day business operations, such as office supplies and IT hardware.

- Facilities MRO – Any items used to maintain your place of business belong in this category. This includes things like light bulbs and safety systems.

Why is MRO important?

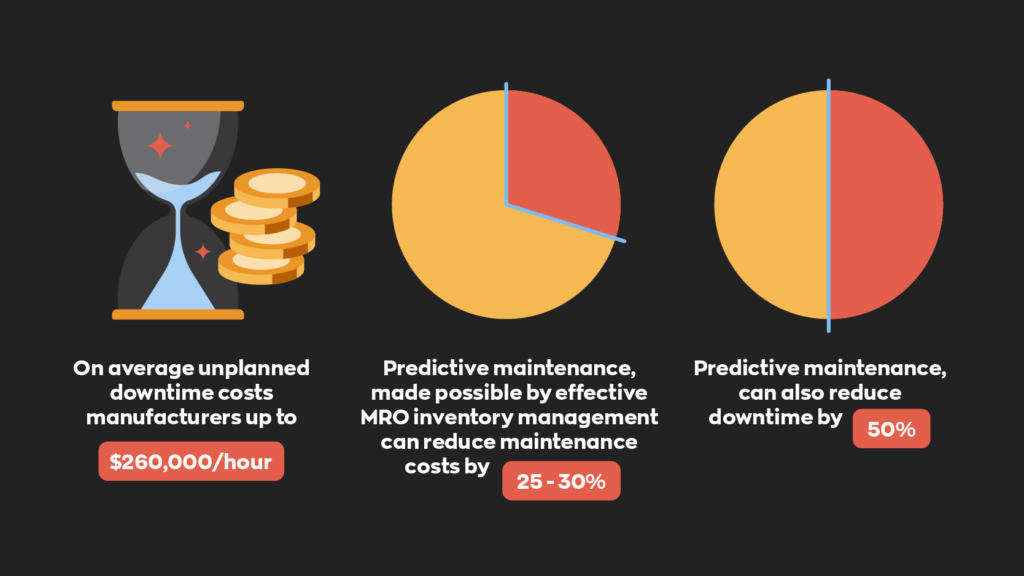

New businesses or companies tend to overlook MRO inventory. In some ways, it’s understandable. After all, it doesn’t generate revenue, so why spend time and resources on it? Well, because it does generate revenue. Just not directly. There’s a famous saying: “A penny saved is a penny earned.”

It’s a saying that applies to running a business. Saving a penny on overhead costs is just as good as earning an extra one. Properly managing MRO inventory is what gives a business the ability to operate in the face of suboptimal conditions.

Properly managing MRO inventory will ensure your business is always running smoothly and prevent unnecessary downtime.

What are the benefits of proper MRO management?

Companies who take the time to manage their MRO supplies see quite a few benefits. We briefly touched on some already, but here’s a more detailed explanation of the benefits.

Workflow efficiency

Staying on top of MRO inventory generally leads to higher efficiency. While mistakes and accidents will inevitably happen, mitigating the effects goes a long way in increasing efficiency.

Cost reduction

At the end of the day, MRO inventory is just that: inventory. And as a result, properly managing it can cut operating costs. However, purchasing MRO supplies and adequately managing them can be tricky. More on that later.

Longer equipment lifespan

Generally speaking, when you keep up with the maintenance of your facility, equipment, and tools, you’ll increase their life span. While it may cost more money in the short term, it’ll pay off in the short term. Think of it as an investment in your business. Properly maintained equipment also operates more efficiently, increasing overall productivity.

What are the consequences of neglecting MRO inventory?

Depending on the industry and manner of products/services provided, there are many possible consequences of neglecting MRO supplies. They can range from delays and downtime to lawsuits and a total shutdown.

Let’s go back to our imaginary electronics company. Say the facility runs out of PPE supplies, and rather than shut down production, the company opts to keep things running. As a result, during production, a mishap leaves one employee with an injury. Something small like that could severely damage the company, not just financially but also its reputation. Not to mention, depending on the industry, neglecting equipment may also go against regulations, which could be grounds for hefty fines or worse.

A more innocuous example would be if your business ran out of light bulbs. While it may seem like a silly inconvenience, it would make it hard for staff to work effectively in the dark.

MRO best practices

Like any other inventory management endeavor, properly managing MRO supplies can be challenging. For starters, traditional forecasting methods, like market trends and customer demand, don’t apply to MRO inventory. However, that doesn’t mean there aren’t some best practices you can follow. Here’s a few to help out.

Classify and rank MRO inventory

Not every MRO product is of equal importance. For example, fixing equipment is more important than repainting it. Figuring out which MRO inventory is more important than others lets businesses prioritize mission-critical equipment above all else. Over time, companies can use this data to help them create a restocking cycle.

Implement safety stock and reorder points

Knowing limits is important. Especially when it comes to MRO supplies, it’s best to purchase as little as possible, while ensuring you don’t run out of stock. To do this, choose realistic reorder points and safety stock levels for your MRO inventory. Remember, MRO inventory should still follow the same basic principles of inventory management, so you should always consider safety stock and reorder points.

Know seasonal trends

The seasons affect most inventory in one way or another. For example, certain times of the year may require longer hours and more production time. This, in turn, will lead to more wear and tear on equipment, which means you’ll need more replacement parts.

Make decisions based on data

Most businesses collect a wide variety of KPIs (key performance indicators), ranging from sales volume to customer information. You may not be able to rely on sales data to predict your MRO inventory needs, but you can still look back at historical data. If you examine what you used in the past, you can better predict what you’ll likely need in the future.

Use software where possible

Before the digital age, everyone had to keep track of things by hand. The accessibility of computers has changed that. Now, software helps businesses across the globe with a variety of tasks. Our inventory management software inFlow can help track MRO inventory in real-time, and it offers integrations with other popular software solutions like QuickBooks Online and Shopify. There is also a built-in barcoding system that helps automate a ton of the work related to managing your MRO supplies.

Conclusion

While often overlooked, MRO inventory plays a crucial role in nearly every business. It plays an indispensable role in ensuring that your business operations continue to run smoothly. Properly managing MRO inventory will minimize downtime, improve efficiency, and help control costs. In a world where time is money, effective MRO inventory management can provide your company with a strategic advantage.

0 Comments