There’s a lot of acronyms in the business world. And not just when it comes to the actual name of the business. For example, you’ve got Limited Liability Companies (LLCs), business 2 business (B2B- that’s us!), Chief Operating Officer (COO), and many others. The world of inventory management is no different. One of the most common acronym mix-ups has to do with inventory identifiers: stock-keeping units (SKUs) and Universal Product Codes (UPCs). While understandable, especially considering the fact that they have similar uses, differentiating SKU vs UPC is essential for effective inventory management.

So, what’s the difference between SKU vs UPC? Are the two interchangeable? Do you always need a UPC? What about a SKU? Today, we’ll review all the differences between UPC vs SKU and what each one means for your business.

SKU vs UPC: What do these acronyms mean?

SKUs and UPCs both serve a similar purpose. They’re both unique codes that represent a product in a database. Businesses can use one or both to keep track of their inventory.

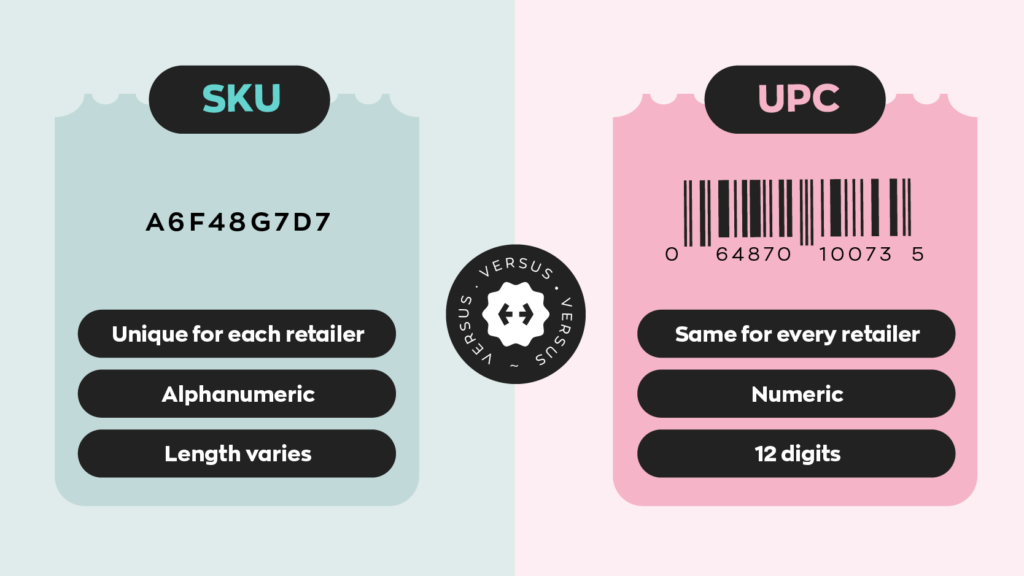

The important distinction between SKU vs UPC is how widely applicable they are. As a general rule of thumb, a SKU is for internal use, while a UPC is for external use. You can also think of a SKU as a closed system, while a UPC is an open system.

This may sound vague and confusing, so here’s an individual description of each.

SKU meaning

As we’ve already established, SKU stands for stock-keeping unit. When a business receives something new in its inventory, it will create a unique identifier for that item. This is known as the SKU number. If the business uses an inventory management system, like our software inFlow, for example, they could connect that SKU to all kinds of information like product description, cost, where it’s stored, and more.

To help illustrate, let’s use different milk products from a typical grocery store as an example. Let’s say that this grocery store sells both 1% and 2% milk. Let’s also say that this store sells each in two different sizes: one liter and two liters.

The SKU for a one-liter carton of 1% might look like this: MLK11

MLK represents “milk,” “1” represents the 1%, and the second “1” represents the carton size. That means that the two-liter carton of 1% milk might look like this: MLK12

And, you guessed it, the one-liter carton of 2% milk will look like this: MLK21

Seems simple, right? You can see all the relevant information at a glance as long as you know what to look for. Giving similar products similar SKUs also helps keep track of things in general. It also helps that directly converting SKUs into barcodes is a simple process.

Remember, though, that we’re keeping these examples simple on purpose. Larger, more complex products will likely have longer, more complex SKUs to match and may contain identifiers for color, size, etc. Despite that, retaining product identifiers and ensuring that the SKUs make sense is still important.

UPC meaning

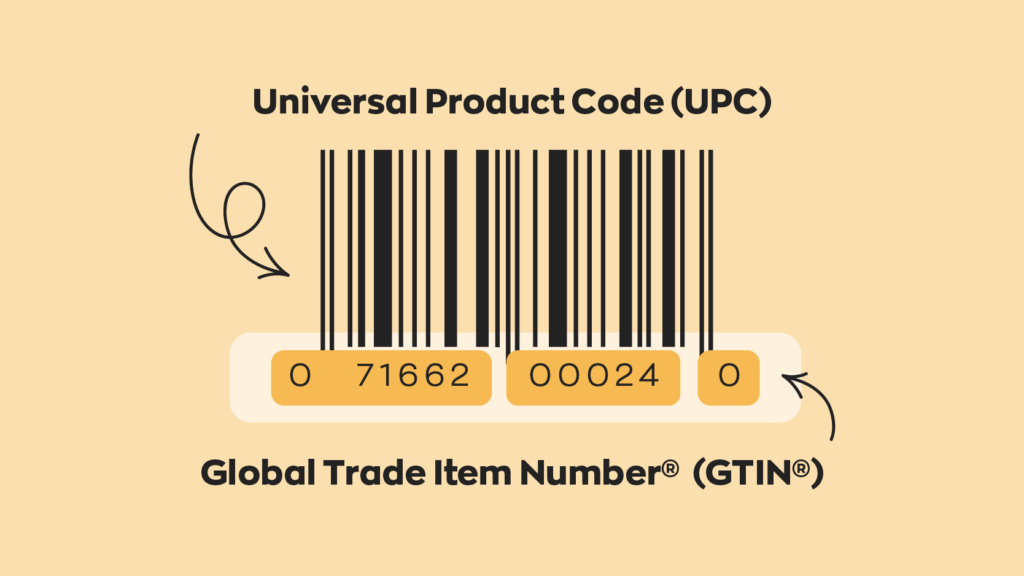

The standard barcode on any product in retail brick-and-mortar stores in North America is a universal product code (UPC). A UPC is a type of barcode symbology used to represent a 12-digit machine-readable numeric code. This is the Global Trade Item Number (GTIN), and it is unique to that specific product.

They serve a similar function, but as the name suggests, they’re meant to be recognized more universally. Unlike a SKU, you can’t just create a UPC; you’ll need to purchase them from Global Standards (GS1) or authorized partners like inFlow.

Once GS1 assigns a UPC to a product, that UPC remains constant throughout the product’s lifespan so long as renewal fees are up to date. However, you can avoid these renewal fees if you buy single GTINs. There’s more to the UPC economy, but we’ll get into that later.

SKU vs UPC: Does your business need both?

Not necessarily, but many businesses do. There’s a few reasons why.

It may be tempting to generate barcodes based on your product’s SKUs. While this is very convenient and would work fine for your internal inventory management, these barcodes would be meaningless to other organizations. So, the bottom line is you’ll need to purchase UPCs if you’re using your barcodes externally.

In this case, you would need a UPC and SKU for your products. But for simplicity, you may want to create your SKU based on the product’s UPC (or, more specifically, its GTIN).

On the other hand, only some businesses need their barcodes recognized externally. And only some companies even use barcodes in the first place. If that’s the case, then having a UPC isn’t necessary. If you’re setting up a barcode system for internal inventory management, you can assign your products a SKU and generate a barcode based on that.

Why are GS1 UPCs so important?

GS1 is a non-profit organization that creates all types of logistical standards worldwide. Their work to keep everything standardized is essential; otherwise, international business would be a nightmare. A sole provider for UPCs allows things to run smoothly as products flow through global supply chains.

GS1 also gives product owners peace of mind. Owners can track their products more effectively, and having a UPC protects their product’s authenticity.

You can purchase official GS1 barcodes from our inFlow GTIN Barcode Shop for only $30 each with no renewal fee. However, if you need more than ten barcodes we would recommend purchasing a company prefix from GS1.

How do businesses keep track of things?

Knowing the difference between SKU vs UPC also raises more questions. For example, as we said, most businesses use both SKUs and UPCs. How do they keep track of that? Especially retail giants like Walmart?

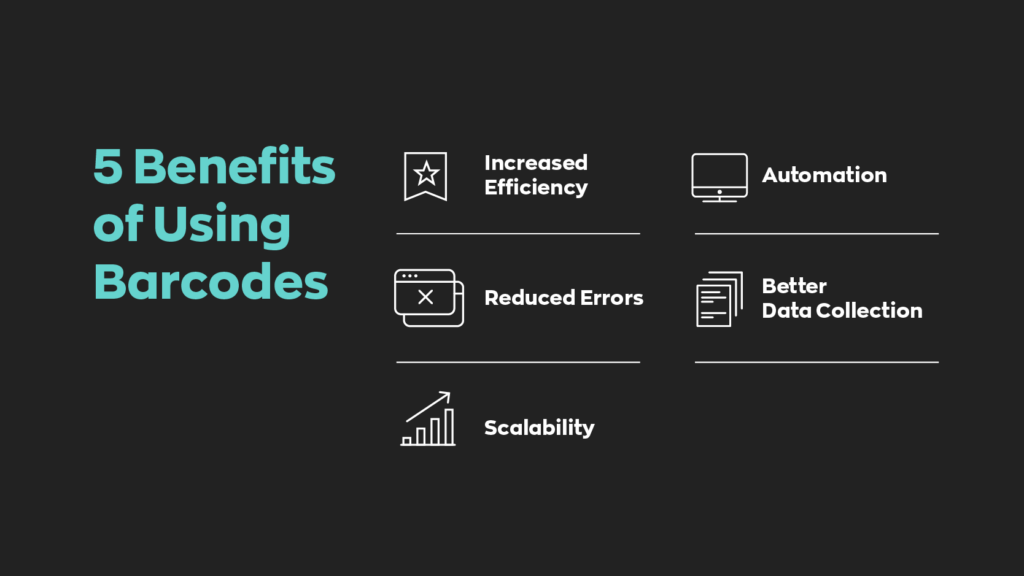

Unfortunately, the sheer amount of data and product movement means that tracking it manually isn’t just impractical– it’s sometimes impossible. We humans are good at many things– understanding nuance, expressing creativity, and so on. But when it comes to processing data, we’re much slower than computers.

And that’s why we are seeing more and more businesses turn to our software inFlow to handle more of their daily operations. We’ve been working on inFlow for over a decade and have been refining it to be the perfect tool to help manage your inventory and assets.

With inFlow, you can track sales, set reorder points for your products, and monitor all your inventory levels in real-time. And that’s just some of the basics. What we’re most proud of with inFlow is the barcoding system we built into the software. You can generate traditional 2D barcodes or QR codes and design labels for your products. You can also print and scan the barcodes right inside inFlow.

And when it comes to SKU vs UPC, it’s perfectly capable of handling both simultaneously.

0 Comments