— 5 minutes reading

Inventory control is simply the process of tracking the quantity, movement, and value of your products.

In the past 11 years of helping small businesses with inventory, we’ve heard many customers call this process both inventory management and inventory control, so we consider the terms to be interchangeable.

Who is inventory control for?

Inventory control is something that business of all sizes should care about. Smaller businesses of five to ten people might be concerned about tying up too much cash in stock, which can hinder the growth of the company. Larger businesses with hundreds of employees might have more cash to allocate, but it can also be easier to over or under order if your logistics and sales departments aren’t communicating well with one another.

Good inventory control practices in place keeps this from happening at any stage of your growth.

It also doesn’t matter what sector you’re in — if you deal with products, then inventory control is something you need to pay attention to. Ecommerce, retail, and wholesale business have a lot of products moving in and out, or they might even be drop shipping some of the items from warehouses far removed from the office.

All of these inventory movements need to be tracked for the business to function profitably. Anyone who has used FBA (Fulfillment by Amazon) knows this because Amazon actually shows you a dollar figure to represent lost sales when you run out of stock.

Here’s a good inventory of inventory management and control:

What do you need to track?

In order to practice inventory control, you’ll need to track the value and quantity of products going in and out of your business. These divide nicely into three sections:

Purchase and sales orders

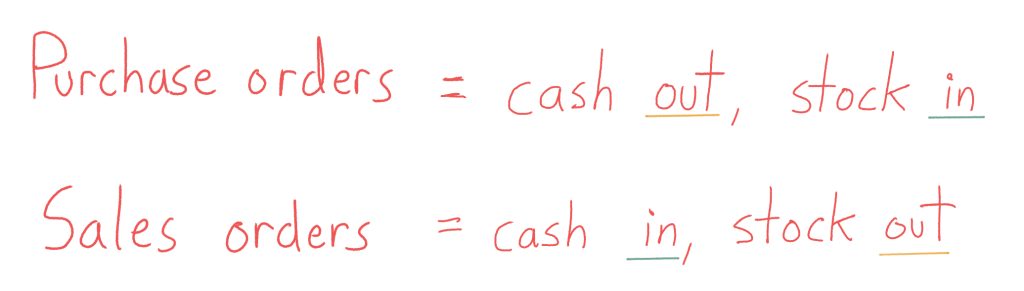

Purchase orders (POs) contain products that you order for your business. If you create products from scratch you might order raw materials, or if you’re a wholesaler, you’ll order products in bulk on your POs. Sales orders (SOs) contain products and services that you sell to your customers.

POs are an inflow of stock and an outflow of cash, while SOs are an outflow of stock and an inflow of cash — good inventory control involves tracking all of these orders right down to their status level. If you see PO-00504, you should be able to tell what’s on the PO, how much it cost your business, and when the products on that order arrived at your business.

Revenue and cost

The other critical aspect of inventory control is tracking revenue and costs.

When you buy products on a PO, you should be tracking the overall cost of each item, as well as the taxes and freight charges associate with each order. You’ll need to build these into a unit cost using the moving average or FIFO/LIFO costing method. Whenever products are sold on a sales order, you should track the revenue per product, minus any discounts and taxes.

By tracking the revenue and cost on each transaction, you’ll make it easy to subtract cost from your revenue and calculate the profit you’re making on each sale on a per-product basis.

Inventory movement and stock levels

As you generate new POs and SOs, your overall level of inventory will rise and fall. The snapshot of your inventory quantities at any given time is called your current stock level, and anything that affects the quantities is called an inventory movement.

Sales and purchases are inventory movements, but there are also a few other kinds.

If you’re transferring inventory from one store to another, that’s called a stock transfer.

If you’re counting or correcting inventory levels based on what’s actually in the warehouse, those movements are called stock adjustments. A warehouse-wide stock adjustment is called a cycle count. Improve inventory control with barcode scanning

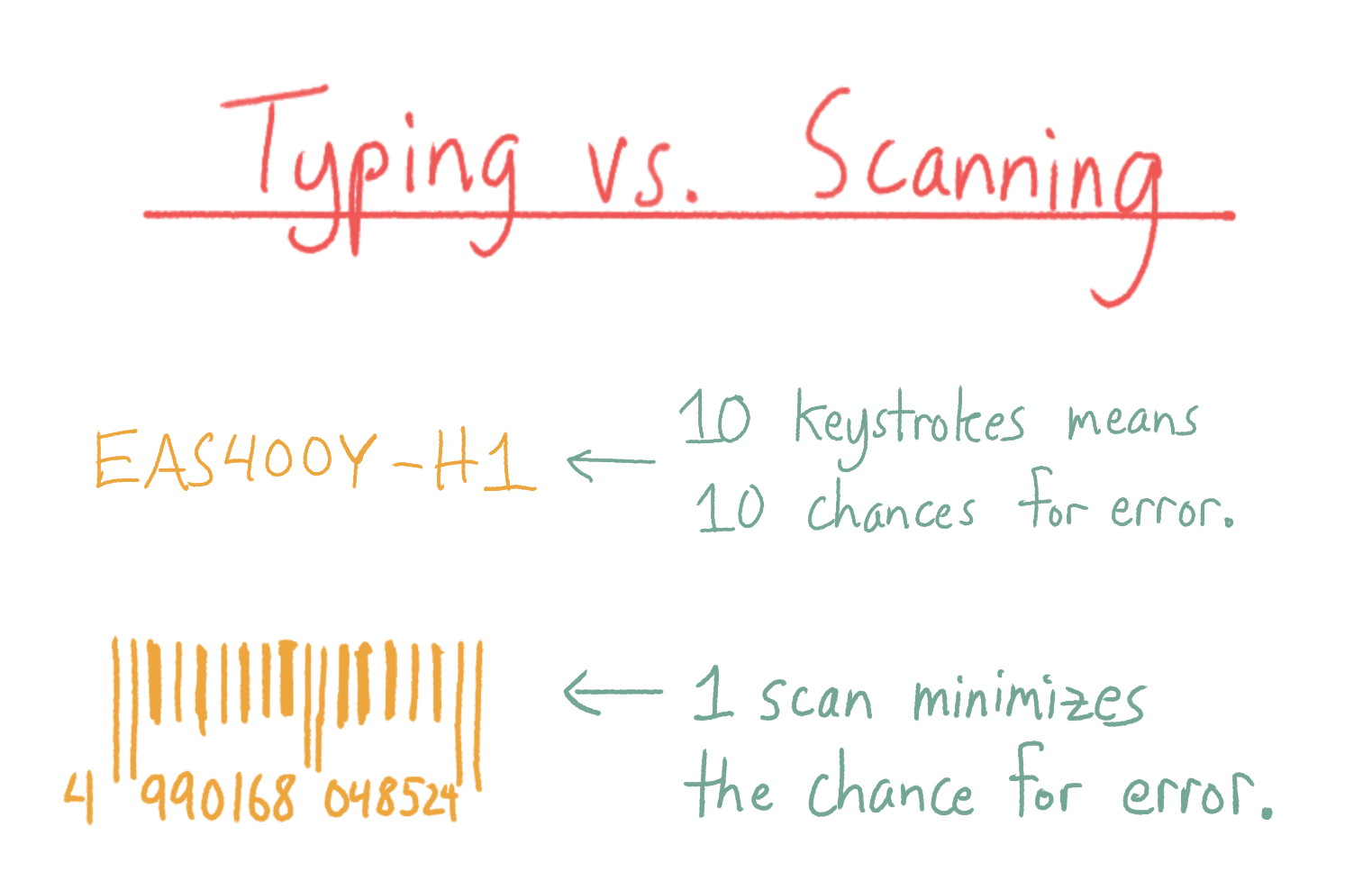

One of the enemies of inventory control is improper data entry. Typos or other mistakes can occur as you enter inventory movements, and this can make your records stray farther and farther from what’s actually on your shelves.

Adapting barcodes and scanners can help to increase your business’ inventory accuracy by cutting down on data entry. You can tie barcodes directly to items, so that you can scan once instead of typing an entire name out.

If you can cut down a longer item name like EAS400Y-H1 to the single beep of a scanner, you’ll be drastically decreasing the chances of errors during data entry.

Not all products can be barcoded, but there’s usually some way to integrate barcodes into your workflow. If you can’t place barcode stickers on your products, you can label the shelves or bins that they’re on, or create a binder or list of barcodes to scan as you fulfill orders.

Those are the basics of inventory control: tracking inventory value, movements, and quantities. If you’d like to a single system to handle all of your inventory, then inFlow Inventory can help.

Our software tracks sales and purchases, quantities across multiple locations, and even reports on profit and costs. Just like the name implies, inFlow Inventory stores your inventory data securely in the cloud, so anyone at your business can check on products and orders from whatever device they’re on.

If you’d like to take the next step in inventory control, check out inFlow Inventory!

how can we reverse a fulfilled SO where erroneously product and price has been changed and saved too.