Knowing what type of inventory your business carries can help you manage it effectively. There are over a dozen types of inventory, but we can break it down into several key categories. Today, we’re looking at the five fundamental types of inventory that every operational manager should know about.

What is inventory?

Inventory refers to all the items your business holds in order to make a profit. This includes both finished goods and raw materials, as well as items that help your business to run properly, like office equipment.

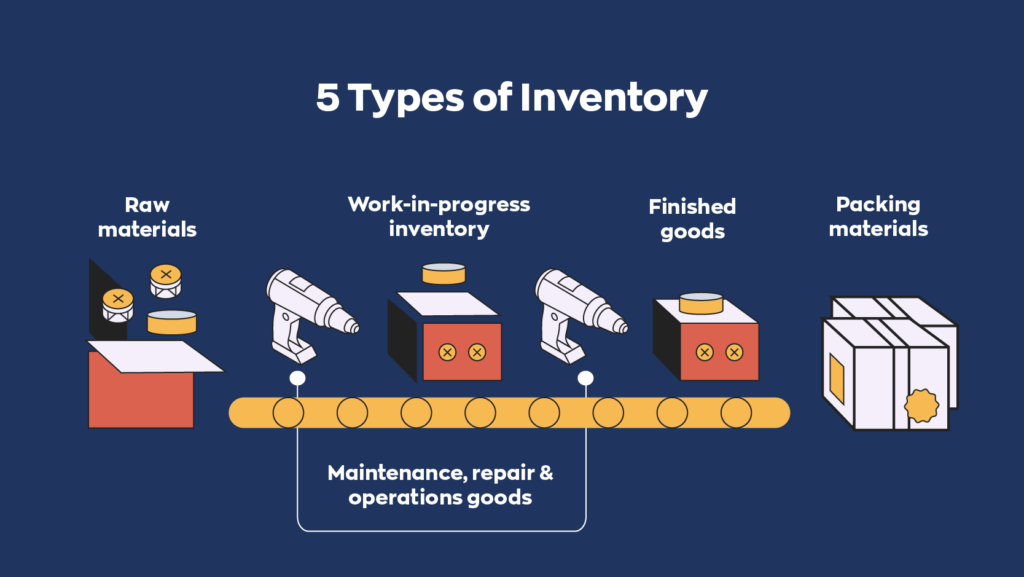

The five types of inventory

The types of inventory you work with depend on your sector and goals. For example, manufacturers will usually hold a wider variety of inventory types than retailers. Here are the five fundamental types:

1. Raw materials

Raw materials are the components we use to make a product. A manufacturer might extract, produce, or buy them from a supplier. Items are only considered raw materials before they are used.

Generally, raw materials fall into one of two categories, direct and indirect. Direct raw materials are the ones that will become part of the final product. For example, these could be ingredients for pizza dough. Indirect raw materials are those which help the process, but don’t go into the finished product, for instance, the fuel needed for an industrial woodfire pizza oven.

2. Work-in-progress (WIP) inventory

A work-in-progress item sits between raw materials and finished goods. This means the item has begun production but is only part of the way through the production process. WIP inventory examples could include suit pants that need to be sewn together or coffee beans that have been roasted and are waiting to be ground.

It is important not to overlook this type of inventory. Not only is it essential for balance sheets, WIP inventory needs careful management. Storing too much WIP inventory and you’ll increase your carrying costs, which means you’ll have more of your cash flow tied up in assets. Too little WIP could cause delays in customer orders. Properly tracking this type of inventory is also helpful for assessing the production process itself. You can track metrics like speed and frequency of production and use the data for more accurate forecasting.

3. Finished goods

Finished goods are completed and waiting to be sold. The number of finished goods you have in stock will depend on many factors, including your inventory management methods.

For example, manufacturers who choose to follow just-in-time methodology will produce and assemble items just as they are needed, rather than carrying excess WIP and finished goods.

4. Maintenance, repair & operations (MRO) goods

MRO goods are inventory items that help you run your business but aren’t a direct component of an item you produce. MRO inventory examples might include office supplies, lab equipment, and machinery.

While these items aren’t destined for customers, they’re still an important inventory type. Imagine, for example, a manufacturing boss buys new tables for their employees’ workstations. Several of the tables are later damaged when the space is reorganized, and so they are sent for repair.

Efficient MRO inventory management will give you clear visibility into the whereabouts and status of the tables and prevent anyone from mistakenly ordering new ones.

5. Packing materials

This inventory type might not seem like the most important, but when not managed properly, packaging costs can add up. You can categorize packing materials as primary, secondary, and tertiary.

- Primary packaging – The innermost packaging that holds your finished product, for example, the bottle that holds hot sauce.

- Secondary packaging – The branded packaging that houses the primary packaging, such as a multi-buy box that holds several bottles of sauce.

- Tertiary packaging – The packaging used for transport, for instance, a cardboard box with separate compartments that prevent the glass sauce bottles from damaging each other.

Why is it important to separate the different types of inventory?

Businesses need to know what type of inventory they’re dealing with so they can manage it properly. This can help you work out how much you spend in different areas and optimize production to boost profitability.

For instance, if you find yourself with low profit margins, knowing exactly what you spend on each type of inventory can help you make the right pricing or supplier decisions. Understanding inventory types will also help you better organize your layout, optimizing it for your warehouse pickers. Maybe you’re storing excess raw materials that are incurring high carrying costs due to shrinkage.

In short, knowing exactly what inventory you have helps you keep a close eye on your operations.

Should you treat the types differently when managing your inventory?

Exactly how you treat the various types of inventory will depend on your operation. The most important thing is to find an inventory management system that works well for you. Then, you can work out the best way to treat your inventory, either in groups or separately.

For example, InFlow’s inventory software allows you to calculate the maximum number of finished products you can build based on the quantity of raw materials you have available.

Importantly, the system treats the quantity available differently to quantity on hand, the first being your raw materials and the second being items that are already part of a work or sales order (e.g., work-in-progress inventory). So, it’s important to log all raw materials as they enter and leave your operations.

Of course, these inventory types are interconnected. Shortages or overstocking can have a rolling effect, so keeping a close eye on the different types of inventory means you can more easily track how items flow through your production.

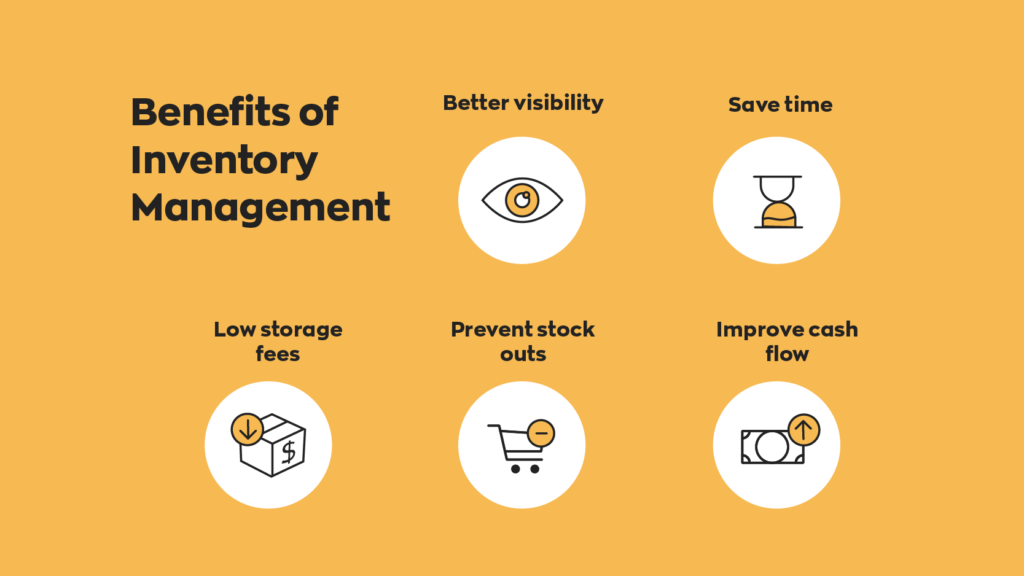

Why is inventory control so important?

Inventory management isn’t just about knowing how many of each item is in stock. As IBM explains, “the goal of inventory management is to have the right products in the right place at the right time”. This is true no matter the types of inventory you deal with.

With the right inventory management systems in place, you can create efficient workflows that reduce costs, optimize space, prevent stockouts, and free up capital. You can receive real-time data and make forecasts and predictions to boost your business.

Good inventory management means not only does your business stay profitable, but it can also deliver on its promises to customers, creating a loyal and happy customer base.

0 Comments