Running a business means wearing many different hats. You’ll need to manage client relationships, maintain the books, and keep up with your assets and inventory. Something you’ll quickly learn, though, is that much of what you do comes down to managing risk. And one of the greatest risks for any business that runs on inventory is a stockout.

A stockout means lost sales, diminishing customer loyalty, and, in extreme cases, could lead to your business going under entirely. After all, in the world of business, every sale counts. So, what exactly is a stockout? How does it happen? And most importantly, what can you do to avoid a stockout?

What is a stockout?

Even as a consumer, you’ve almost certainly experienced a stockout before. As its name suggests, the term refers to when a business completely exhausts its product supply. It could be anything, from everyday items to 72-inch televisions. While the financial implications of a lost sale are obvious, there are other effects that could negatively affect your business. Thankfully, there’s ways to mitigate the risks.

What causes stockouts?

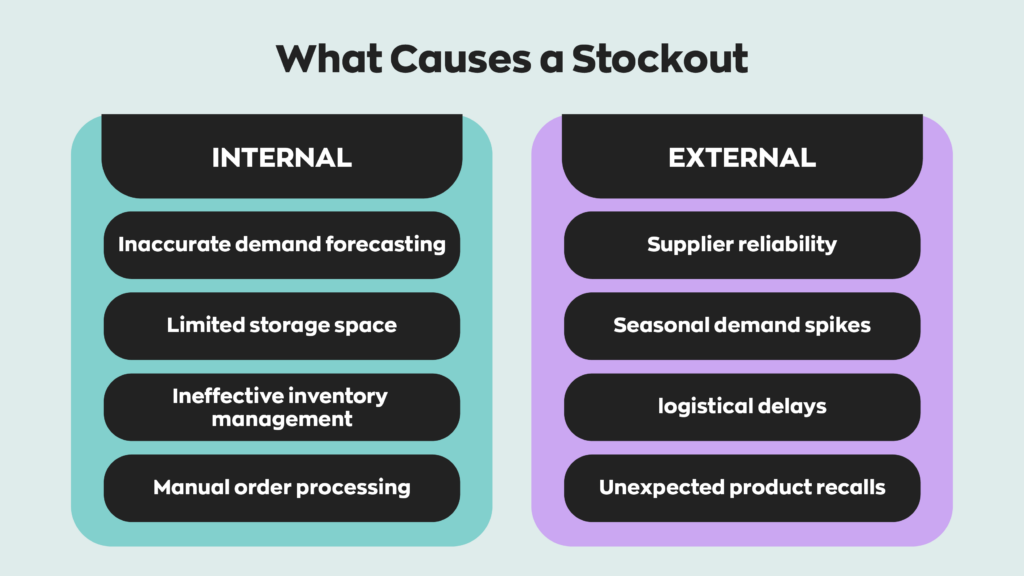

Any business can fall victim to a stockout for several reasons. Some common causes of a stockout are:

- Poor inventory management—Inefficient inventory management is the most common cause of a business running out of stock. If you’re not closely monitoring the flow of goods through your business, it’s only a matter of time before you experience a stockout. Here’s the good news. Improving your inventory management is one of the easiest things to remedy.

- Supply chain disruptions—A stockout can occur anywhere on the supply chain, affecting the flow of goods. Take COVID-19 for example. It had a profoundly negative effect on supply lines worldwide, and no one could predict it. Regardless of how well you manage your inventory, supply chain disruptions can and will trickle down to your business.

- Inaccurate demand forecasting—Demand for products will fluctuate from season to season, and accurately forecasting the needs of your business can be tricky. Using historical data and looking at market trends are great places to start if you aim to forecast demand accurately.

Of course, countless other issues can cause your business to run out of stock. For example, if you buy and sell internationally, maybe there’s new legislation. Even an error on a spreadsheet could easily cause a stockout.

How will a stockout affect your business?

Depending on the type of business you run, a stockout will impact your business in different ways. These are some negative implications you can expect to experience in the event of a stockout:

- Lost sales and revenue—No matter what industry you’re in, a stockout will result in lost sales and revenue. For example, retailers will have fewer products on their shelves. Manufacturers will have to shut down entire assembly lines if their raw materials run out of stock, which will cause missed shipments. Construction workers may be unable to complete a project on time without the proper materials.

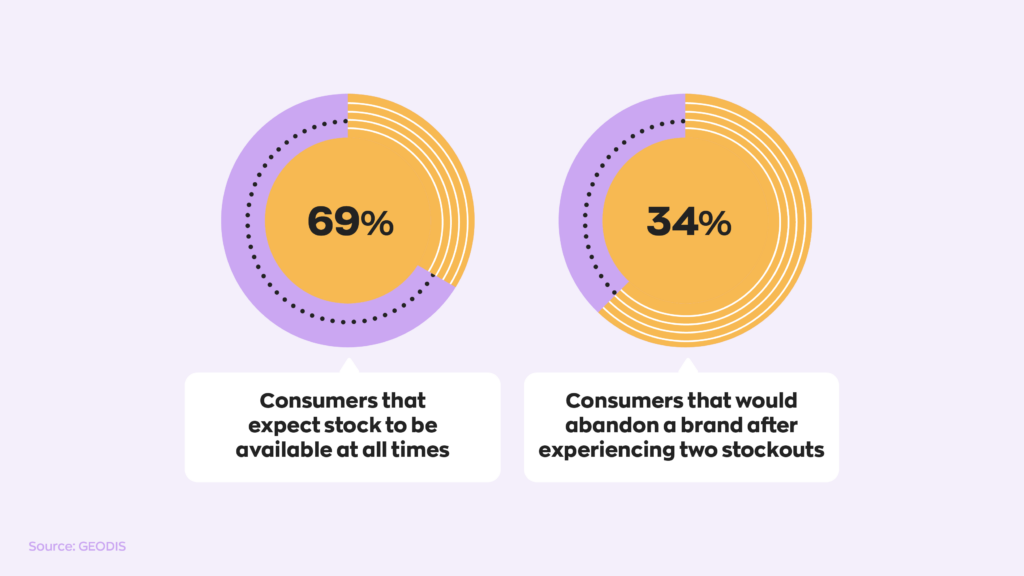

- Decreased customer loyalty—In the modern age of business, things move at breakneck speeds. If you experience a stockout, chances are the consumers aren’t going to wait around for you to get it sorted. They’ll take their business elsewhere. The effects of lower customer loyalty are difficult to quantify but will often make or break a business.

- Damaged reputation—When you experience a stockout as a consumer, your faith in that business diminishes. Over time, this can severely damage your brand’s reputation and cause customers to flee. For example, let’s say you hire an HVAC company to fix your furnace, and they take a week to get the job done due to a stockout. It goes without saying you’ll never recommend that company to a friend; in fact, you may warn others to actively avoid them.

How can you prevent stockouts?

Unfortunately, preventing them entirely is nearly impossible. This is because, as we established, a stockout can arise because of an issue anywhere in the supply chain. You may be in control of what happens under your purview, but controlling other establishments is out of the question.

As a result, it’s generally better to focus on reducing them as much as possible. Most of that comes down to having infrastructure in place beforehand. Here are some best practices you should consider implementing to help prevent a stockout.

Maintain a healthy level of inventory

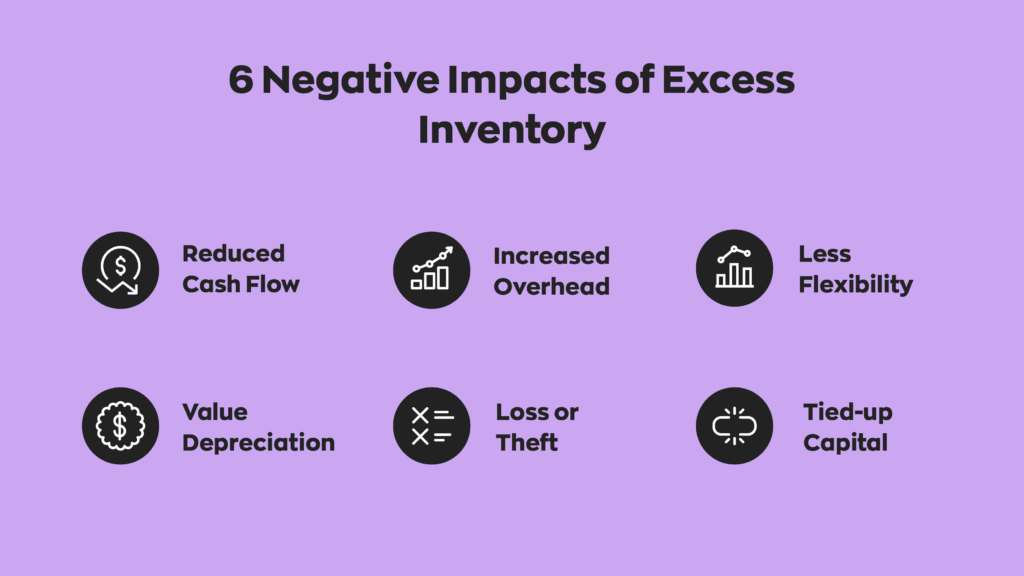

When you keep a surplus of inventory, it will certainly help prevent the potential for a stockout. However, it’s essential to understand that there is such a thing as too much inventory. Carrying excess inventory is also harmful to your business. If you keep a surplus of too many products, your carrying costs will eat away at your overhead.

Perform regular cycle counts

While it won’t help with supply chain issues, keeping tight control of your inventory helps avoid short-term stockouts. When you perform a cycle count, you ensure that what you have on paper matches what you have in storage. After all, inventory shrinkage is an inevitable part of doing business.

Establish solid supply lines

One thing you can do ahead of time is invest in finding reliable supply lines. Whether you’re a retailer or a manufacturer, you need to get your inventory from somewhere. Take the time to find reliable suppliers with a good reputation. But don’t limit yourself to just one supplier. If your business depends on a single supplier, you become more vulnerable to stockouts.

Use safety stock and reorder points

Keeping a certain amount of safety stock available for those “just in case” moments is common among business owners. Safety stock also plays into reorder points, which are another great way to reduce the occurrence of stockouts. You can calculate reorder points for each of your products to give you an indication of when you need to reorder more stock.

We put reorder points into inFlow ages ago because we know how important they are to business owners. When inFlow users’ stock dips below a reorder point, they’ll be notified immediately. This empowers them to order more stock at the perfect time to ensure they’ve always got what they need when they need it.

Use inventory software

Preventing a stockout comes down to preparation. Much of that preparation requires implementing processes, careful counting, and some data collection. Having proper inventory software helps with all of this.

In addition to automatic reorder points, inventory control software like inFlow keeps track of your inventory in real-time. We make managing your suppliers simple by giving you easy access to their details, past order histories, and lead times, all in one place. Our reporting features will also help you analyze historical sales data and give you the information you need for accurate demand forecasting.

To sum it up

Stockouts can have a profound impact on businesses beyond the initial financial blow. While they may be inevitable, that doesn’t mean you shouldn’t take measures to reduce their frequency. Focus on the things you can control to avoid running out of stock, like implementing the right processes and using the right tools. These things can make a world of difference and protect your business from future stockouts.

0 Comments